$3,500.00 – $21,500.00Price range: $3,500.00 through $21,500.00

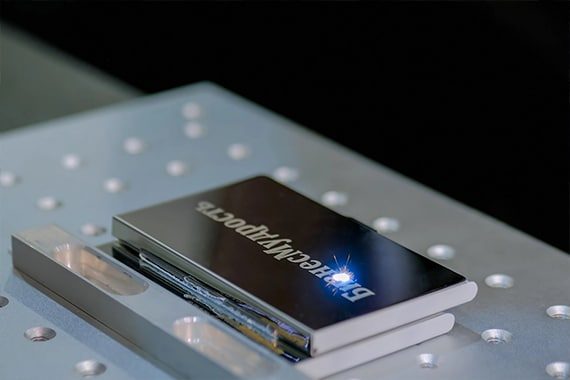

The flying design of this laser marking machine allows for the high-speed, continuous marking of moving materials. Ideal for production lines, it ensures precision and efficiency while marking large volumes of items. This innovative design eliminates the need for manual handling, streamlining workflows, and increasing overall productivity in fast-paced environments.

The fiber laser generator delivers high-quality, consistent marking with exceptional precision. Known for its long lifespan and energy efficiency, it provides powerful and stable performance across various materials. Ideal for high-speed, high-precision applications, this advanced generator ensures minimal maintenance and maximum productivity, making it perfect for industrial use.

The air cooling device is designed to efficiently regulate the temperature of the laser marking machine, preventing overheating during prolonged operations. By providing continuous airflow, it ensures stable performance and extends the lifespan of the system. This compact, reliable feature is essential for maintaining high-quality marking results with minimal downtime.

The advanced control system offers intuitive, precise management of the laser marking machine. Featuring user-friendly software, it allows for easy operation, custom configurations, and quick adjustments. With real-time monitoring and enhanced functionality, this system ensures consistent performance, high accuracy, and seamless integration into automated production environments.

The high-speed galvo scanner enables rapid, precise laser marking by using advanced galvanometer technology. It ensures quick, accurate beam positioning for detailed, high-quality marks on a variety of materials. This system optimizes production efficiency, offering enhanced speed without compromising on precision or consistency, ideal for high-volume applications.

The high-precision field lens ensures exceptional focus and clarity during laser marking operations. Designed to minimize distortion, it delivers precise, uniform laser beams across a wide range of materials. This advanced lens enhances marking quality, enabling fine detail and superior accuracy for intricate designs and high-resolution applications.

The red dot pointer simplifies material positioning by visibly indicating the laser's focal point. This easy-to-use feature improves alignment accuracy, reducing setup time and enhancing workflow efficiency. It ensures precise marking results, helping operators quickly adjust and align materials for consistent, high-quality output in various applications.

The safety interlock system ensures secure operation by automatically shutting down the machine if safety doors or panels are opened during operation. This feature protects users from potential laser exposure and accidents, enhancing workplace safety. It's a crucial component for meeting industry safety standards and providing a secure working environment.

| Model | VIM20FF | VIM30FF | VIM50FF | VIM60FF | VIM70FF | VIM100FF |

| Laser Power | 20W | 30W | 50W | 60W | 70W | 100W |

| Laser Wavelength | 1080nm | |||||

| Laser Generator | Raycus, IPG | |||||

| Minimum Line Width | 10 Microns | |||||

| Minimum Characters | 0.15mm | |||||

| Usage Environment | Clean and Dust-Free or Dust-Less | |||||

| Graphic Format Supported | bmp, jpg, gif, png, tif, ai, dxf, dst, plt, etc | |||||

| Laser Module Life | >100000 Hours | |||||

The smoke exhaust system is an essential upgrade for maintaining a clean and safe working environment. It efficiently captures and filters smoke, fumes, and dust generated during the laser marking process. This system helps to improve air quality, ensuring compliance with safety standards and providing a healthier workspace for operators.

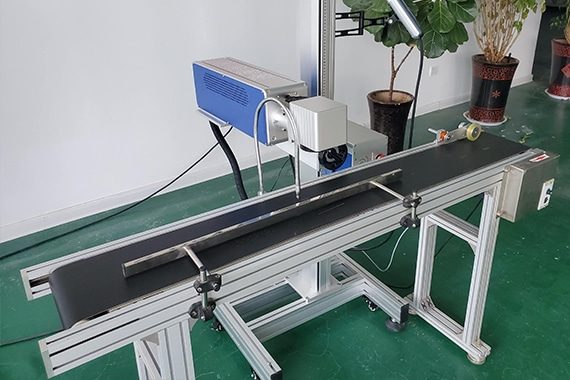

The conveyor system enhances workflow efficiency by automatically moving materials through the laser marking process. Designed for high-volume production, it ensures consistent and smooth material handling, reducing downtime and increasing productivity. Ideal for continuous marking on various materials, the system helps streamline operations and maintain high throughput.

The marking sensor enhances precision and efficiency by detecting the material’s position and ensuring accurate alignment for laser marking. This advanced feature minimizes errors, optimizes focus, and ensures consistent, high-quality results. Ideal for intricate designs and automated workflows, it streamlines the marking process for various applications and materials.

The autofocus system automatically adjusts the laser’s focal length to achieve optimal precision, ensuring clear, sharp markings across different material thicknesses. This feature eliminates the need for manual focus adjustments, enhancing productivity and accuracy. Perfect for applications requiring consistent quality and high-efficiency processing.

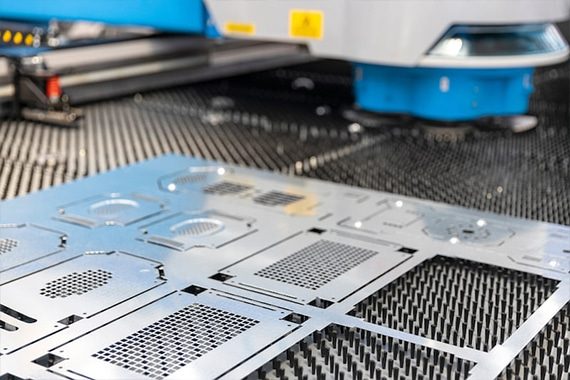

Our laser marking machines offer incredible accuracy, ensuring clean, sharp, and clear markings every time. Whether it’s a logo, barcode, or serial number, you can count on perfect results.

These machines can mark a wide range of materials, from metals and plastics to ceramics and glass. No matter the material, our machines deliver precise results.

Laser markings are permanent, meaning they won’t fade, peel, or wear off. This makes them ideal for applications that require long-lasting identification, traceability, and branding.

Laser marking uses no chemicals, inks, or solvents, making it an environmentally friendly choice. It produces minimal waste, reduces pollution, and has a low environmental impact.

Our laser marking machines are designed with user-friendliness in mind. With simple controls and intuitive software, you’ll be able to start marking your products right away.

By reducing the need for consumables like ink or labels, and speeding up the marking process, our laser marking machines help you save money over time.

Copyright © 2025 Victory Industry Inc. All rights reserved.

4 reviews for VIM-FF Laser Marking Machine

Benjamin –

Impressive performance and great value for the price. The fiber laser marking machine works perfectly on both metals and plastics. The machine is easy to use, and the output is always sharp and precise.

Chloe –

This machine is a real game-changer. It marks with precision and speed, and the results are always crisp and clean. We’ve been able to speed up our production while maintaining top-notch quality.

Eli –

Fantastic tool for our business. It marks a variety of materials with excellent precision, and the machine is reliable and easy to use. It has drastically improved our production and product quality.

Mason –

We’ve been using this fiber laser marking machine for a few weeks now, and it’s been a great addition. The quality of markings on various metals is excellent, and the machine is very easy to operate.