$3,600.00 – $8,100.00Price range: $3,600.00 through $8,100.00

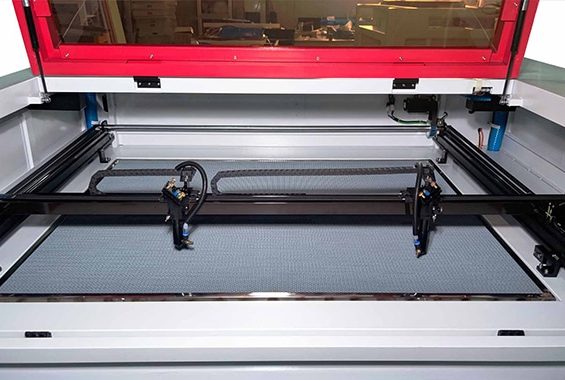

The dual laser cutting head enhances cutting efficiency by allowing simultaneous processing of two materials or multiple cutting paths. With advanced focus control and improved beam quality, it delivers precise, high-speed cuts across various materials. This feature maximizes productivity, reduces cycle times, and improves overall machine performance for complex tasks.

The high-performance CO2 laser tube delivers powerful, consistent laser output for precise cutting and engraving. Designed for durability and high efficiency, it ensures stable performance over extended periods. With excellent beam quality and energy conversion, this laser tube provides optimal cutting speeds and exceptional results on a variety of materials.

The precision linear guide ensures smooth and accurate motion during the cutting process, minimizing friction and enhancing stability. Designed for high-speed operations, it provides exceptional precision and durability, reducing wear and tear. This feature guarantees consistent performance and long-term reliability, ensuring optimal cutting quality and efficiency in demanding applications.

The high-precision stepper motor offers exceptional control and accuracy, ensuring smooth, precise movement during the laser-cutting process. With its advanced technology, it delivers consistent positioning, reducing errors and improving cutting quality. This motor enhances machine performance, providing high-speed operation with superior reliability for demanding industrial applications.

The efficient belt drive system ensures smooth, high-speed movement with minimal friction, enhancing cutting precision and reducing energy consumption. Designed for durability and low maintenance, it delivers reliable performance even in high-demand environments. This system improves overall machine efficiency, providing fast, accurate cuts while extending the lifespan of critical components.

The aluminum blade worktable provides a durable and stable surface for precise cutting operations. Designed with high-strength aluminum, it ensures minimal wear and deformation over time. Its optimized structure supports various materials, promoting excellent cutting accuracy and efficiency. Lightweight yet robust, it enhances overall machine performance and long-term reliability.

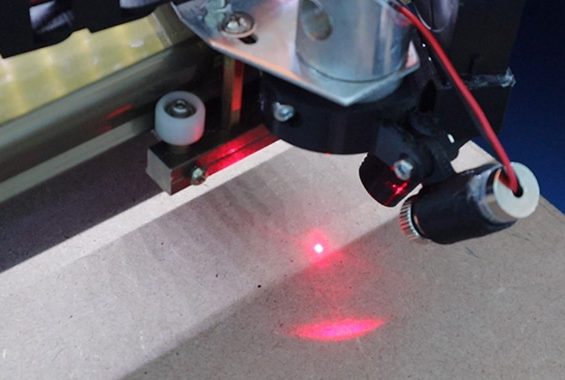

The precision red dot pointer is an optional feature that assists in accurate material positioning by projecting a visible red dot onto the workpiece. This guide allows operators to align materials precisely, ensuring clean, accurate cuts. It enhances workflow efficiency, reduces setup time, and ensures high-quality results, especially for intricate designs.

The advanced control system integrates cutting-edge software and hardware to optimize the laser-cutting process. With intuitive user interfaces and real-time adjustments, it ensures precise control, enhancing cutting speed and quality. This system improves operational efficiency, reduces errors, and offers advanced features for complex tasks, making it ideal for high-performance applications.

| Model | VIC6040D | VIC9060D | VIC1390D | VIC1610D | VIC1318D | VIC1325D | VIC1530D |

| Working Area | 600*400mm | 900*600mm | 1300*900mm | 1600*1000mm | 1300*1800mm | 1300*2500mm | 1500*3000mm |

| Laser Type | CO2 Laser | ||||||

| Working Table | Knife Table or Honeycomb Table | ||||||

| Laser Power | 80-600W | ||||||

| Power Supply | 220V/50HZ, 110V/60HZ | ||||||

| Min Line Width | ≤0.15mm | ||||||

| Position Accuracy | 0.01mm | ||||||

| Repetition Accuracy | 0.02mm | ||||||

| Cutting Speed | 150mm/s | ||||||

| Control System | Ruida (USB Interface) | ||||||

| Graphic Format Support | PLT, DXF, BMP, JPG, AI, etc | ||||||

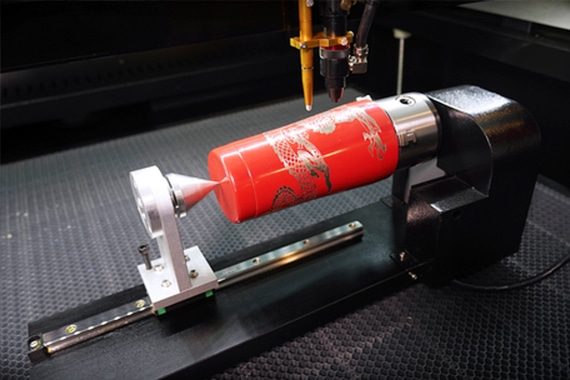

The rotary attachment is an optional configuration that allows the CO2 laser cutting machine to cut cylindrical and round materials with precision. Perfect for processing tubes, pipes, and other curved surfaces, it expands the machine’s capabilities, providing versatility for custom applications and ensuring consistent, high-quality results across a variety of shapes.

The industrial water chiller is an optional configuration that provides reliable cooling for the CO2 laser cutting machine’s components, ensuring consistent performance during extended use. It helps maintain optimal temperature levels, preventing overheating and reducing the risk of damage. This feature improves cutting precision, enhances machine longevity, and minimizes downtime.

The exhaust system is an optional configuration designed to efficiently remove fumes, dust, and gases generated during the CO2 laser-cutting process. It helps maintain a clean, safe working environment by improving air quality and ensuring compliance with safety regulations. This system enhances machine performance and operator comfort during operation.

The gas supply system is an optional configuration that provides a steady and controlled flow of gases, such as oxygen, nitrogen, or compressed air, to the CO2 laser cutting machine. It ensures optimal cutting conditions, improves material quality, and enhances cutting efficiency, making it essential for achieving precision and high-quality results.

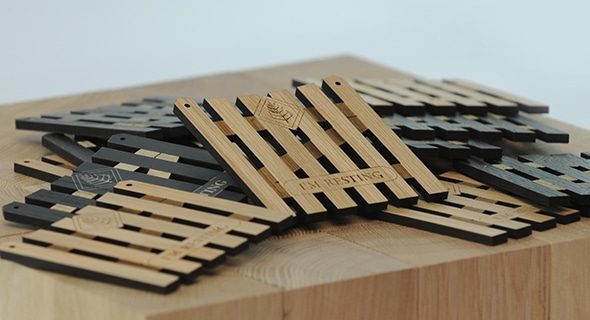

Our machines deliver clean, accurate cuts every time, whether you're working with carbon steel, stainless steel, or other metals. You can count on perfect results with minimal waste.

Victory Industry laser cutting machines are designed for speed. They cut faster, helping you get more done in less time without compromising on quality.

Our laser-cutting machines are energy-efficient and easy to maintain, helping you save money in the long run. Plus, the precise cuts reduce material waste.

You don’t need a laser expert to operate our laser-cutting machines. They feature a simple interface, making them easy to set up and use.

Our team is always here to help. We provide installation, training, and support to ensure your machine works smoothly.

Our laser cutting machines are made with durable materials, ensuring long-lasting performance, even with heavy use.

Copyright © 2025 Victory Industry Inc. All rights reserved.

4 reviews for VIC-D Laser Cutting Machine

Luca –

This machine has been a real time-saver for our shop. We cut wood, plastic, and acrylic with precision, and the machine operates smoothly without any issues. Worth the investment for any workshop.

Sebastian –

Perfect for our engraving and cutting needs! This machine is fast and accurate, and it has helped us complete jobs much faster. It’s easy to use, and customer support has been excellent.

Charlotte –

This CO2 laser cutting machine has been fantastic for our manufacturing process. It’s simple to use, and quick, and the results are always clean and professional. We’ve been able to take on more projects.

Amelia –

We’ve been using this laser-cutting machine for a few months, and the results are fantastic. The cuts are clean and precise every time. It’s easy to set up and maintain—great value for the price.