$21,300.00 – $166,000.00Price range: $21,300.00 through $166,000.00

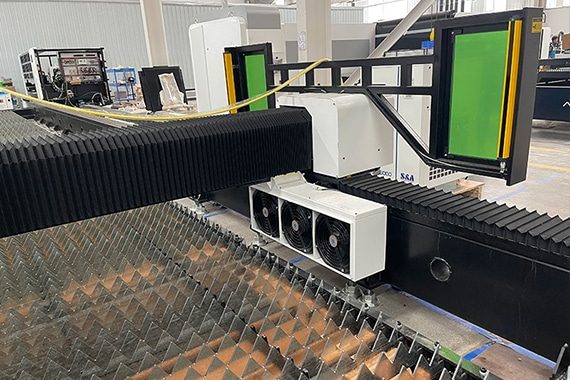

The advanced laser cutting head is designed for precision and efficiency, ensuring high-quality cuts with minimal distortion. It delivers exceptional performance across various materials and features automated focus adjustment, advanced cooling technology, and superior stability. Ideal for demanding industrial applications, it enhances cutting speed and accuracy.

The powerful laser generator offers unmatched cutting performance with high energy output and consistent beam quality. Engineered for precision, it enables fast, clean cuts across various materials. Its advanced design ensures long-term reliability, high efficiency, and minimal downtime, making it the ideal solution for demanding industrial applications.

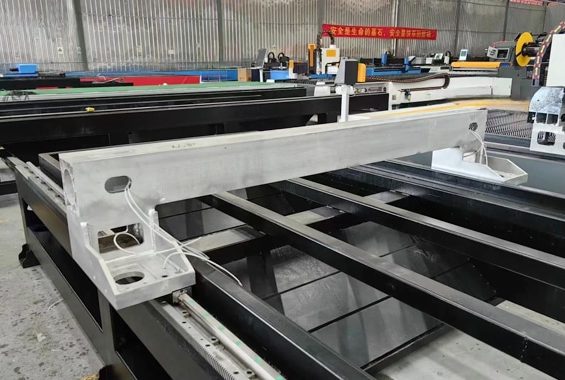

The heavy-duty tube welding bed is engineered for maximum stability and strength, providing a solid base for precision cutting. Built from high-quality welded tubes, it minimizes vibrations and deformation during operation, ensuring accurate results. This robust design enhances machine durability and is ideal for handling demanding high-load industrial applications.

The aviation aluminum beam is lightweight yet incredibly strong, offering superior rigidity and durability. Engineered from high-grade aviation aluminum, it minimizes vibrations and ensures smooth, precise movement during cutting operations. This advanced material enhances overall machine performance, improving cutting speed and accuracy while maintaining long-term reliability in demanding industrial environments.

The secure closed enclosure provides a safe, controlled environment for the laser cutting process. Designed with high-quality materials, it effectively contains light and fumes, ensuring operator safety and compliance with regulations. This sturdy enclosure also minimizes noise and prevents contamination, promoting a clean, efficient, and secure working environment.

The high-performance servo motor delivers exceptional speed, precision, and reliability. Designed for seamless motion control, it ensures smooth and accurate cutting with minimal energy consumption. Its advanced technology allows for quick response times and superior positioning accuracy, making it an ideal choice for high-speed, high-precision fiber laser cutting applications.

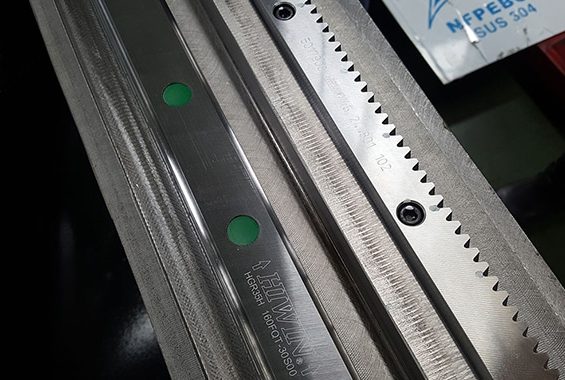

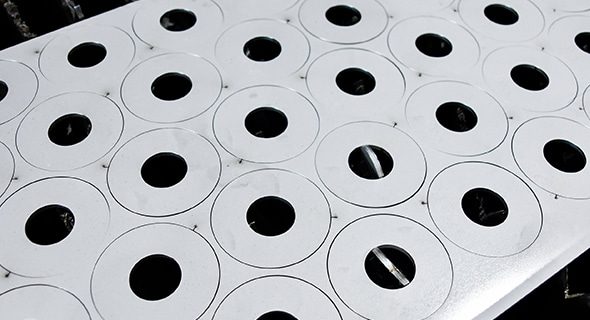

The high-precision linear guides ensure smooth, accurate movement along the cutting axis, minimizing friction and wear. Engineered for exceptional stability and reliability, they provide consistent performance in high-speed operations. With superior alignment and minimal maintenance, these guides enhance cutting precision and contribute to the machine's overall longevity and efficiency.

The advanced control system integrates cutting-edge software with intuitive interfaces to deliver precise, real-time control over the laser cutting process. Featuring advanced algorithms and user-friendly operation, it ensures optimized cutting paths, enhanced efficiency, and consistent quality. This system boosts productivity while reducing errors, making it ideal for complex, high-speed applications.

| Model | VIB3015 | VIB4015 | VIB4020 | VIB6015 | VIB6025 |

| Cutting Area | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2500mm |

| Laser Head | Raytools, WSX, BOCI, Osprey | ||||

| Laser Power | 1500-20000W | ||||

| Laser Generator | Raycus, MAX, IPG | ||||

| Control System | CypCut, Weihong | ||||

| Servo Motor And Driver | Fuji, Delta, Yaskawa | ||||

| Guide Rails | Taiwan Linear Rails | ||||

| Reducer | Japan Shinbo, France Mortori | ||||

| Max. Acceleration | 1.4G | 1.3G | |||

| Z Axis Travel | 300mm | ||||

| Positioning Accuracy | 0.05mm | ||||

| Repositioning Accuracy | 0.03mm | ||||

The smoke purifier system is an optional configuration designed to capture and filter harmful fumes and particles generated during the laser-cutting process. By maintaining a cleaner and safer working environment, it reduces health risks and complies with environmental regulations. This system ensures optimal air quality and enhances overall machine performance.

The high-pressure reducing valve is an optional configuration that ensures precise control of gas pressure during the laser-cutting process. By regulating high-pressure gases to optimal levels, it improves cutting quality, reduces gas consumption, and enhances system safety. This feature is ideal for maintaining consistent performance across various materials.

The air compressor is an optional configuration that provides a consistent and reliable air supply for optimal laser-cutting performance. Designed to deliver high-pressure, clean air, it enhances cutting speed and quality, while preventing contamination of sensitive components. Ideal for high-volume operations, it ensures efficient and continuous machine performance.

The safety light curtain is an optional configuration that enhances operator safety by creating an invisible barrier around the machine. It detects any unintended entry into the cutting area, instantly halting operations to prevent accidents. This feature ensures compliance with safety standards while maintaining high productivity and machine protection.

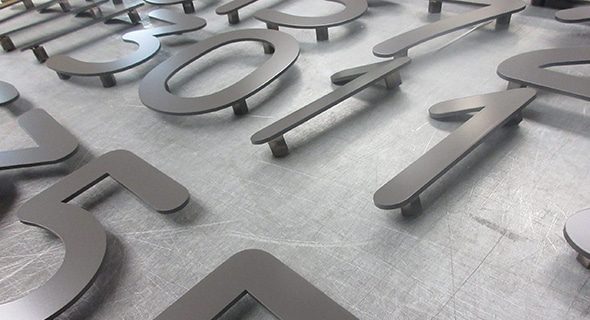

Our machines deliver clean, accurate cuts every time, whether you're working with carbon steel, stainless steel, or other metals. You can count on perfect results with minimal waste.

Victory Industry laser cutting machines are designed for speed. They cut faster, helping you get more done in less time without compromising on quality.

Our laser-cutting machines are energy-efficient and easy to maintain, helping you save money in the long run. Plus, the precise cuts reduce material waste.

You don’t need a laser expert to operate our laser-cutting machines. They feature a simple interface, making them easy to set up and use.

Our team is always here to help. We provide installation, training, and support to ensure your machine works smoothly.

Our laser cutting machines are made with durable materials, ensuring long-lasting performance, even with heavy use.

By submitting your information, you’re taking the first step towards a partnership that redefines what’s possible in laser cutting. Our team will promptly reach out to discuss your unique requirements and guide you through enhancing your manufacturing capabilities with Victory Industry’s laser-cutting solutions.

Copyright © 2025 Victory Industry Inc. All rights reserved.

4 reviews for VIB Laser Cutting Machine

Isabella –

I was hesitant at first, but now I can’t imagine our business without it. The machine is reliable, and efficient, and handles everything we throw at it with ease. Highly recommend!

William –

The machine works like a charm! It’s improved our workflow, and the maintenance is minimal. I’ve been recommending it to other businesses in my industry for sure.

Zoe –

I’ve been using this fiber laser for several months now, and it’s been fantastic. The setup was simple, and the cutting quality was always consistent. I’m very pleased with the purchase.

Michael –

Fantastic purchase for our workshop. It’s a lot faster than our previous laser-cutting machine, and the quality is much better. It’s made a big difference in our overall productivity.