Introduction

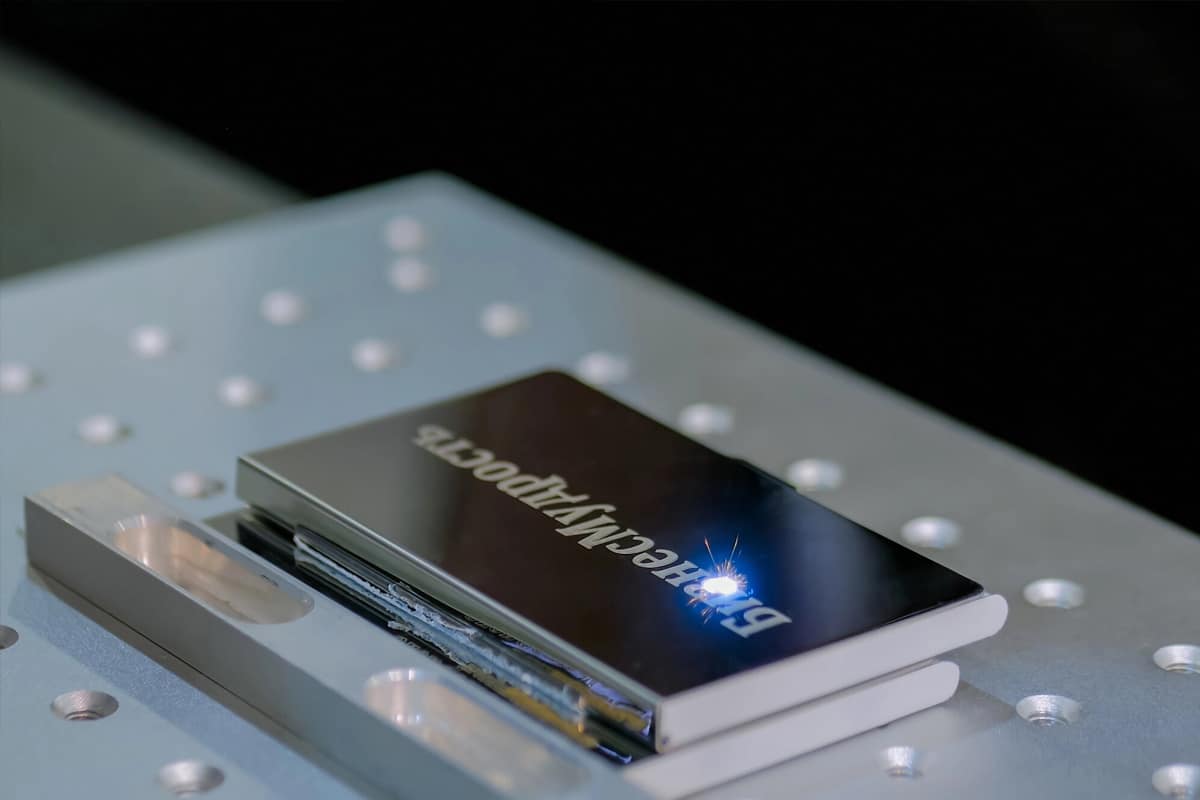

MOPA Laser Marking Machines

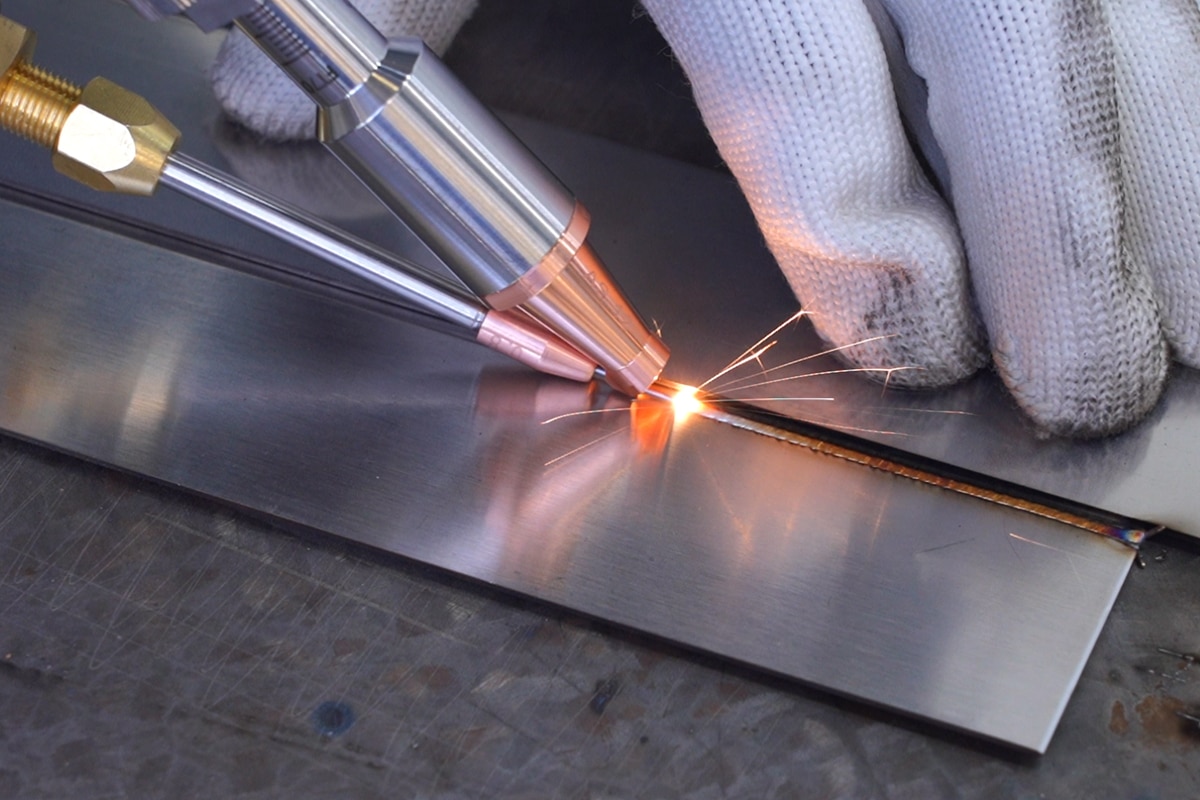

Discover the power and precision of our continuous laser cleaning machines, designed to meet the diverse needs of modern industries. Whether you’re looking to remove rust, paint, oil, or other surface contaminants, our machines deliver exceptional cleaning performance with minimal environmental impact. The innovative laser technology allows for a non-contact, non-abrasive cleaning process that protects your equipment while ensuring a thorough and efficient result.

Our range of continuous laser cleaning machines is suitable for various industries, from automotive and aerospace to heavy manufacturing and maintenance. These machines provide continuous operation, making them ideal for high-volume production environments. With adjustable settings for different materials and surface conditions, our laser cleaning solutions offer unmatched flexibility and precision.

-

VIM-MD Laser Marking Machine

Rated 5.00 out of 5$3,000.00 – $13,000.00Price range: $3,000.00 through $13,000.00 Select options This product has multiple variants. The options may be chosen on the product page

Applications

Advantages of MOPA Laser Marking

Enhanced Precision

MOPA technology offers exceptional control over pulse duration, enabling precise, high-contrast markings with fine details, ensuring consistent and accurate results across a variety of materials and applications.

Versatility in Materials

The MOPA laser marking machine delivers outstanding performance on a wide range of materials, including metals, plastics, ceramics, and glass, making it ideal for diverse industries such as automotive, electronics, and jewelry.

Adjustable Pulse Durations

With adjustable pulse duration, the MOPA laser allows for flexible settings, giving users the ability to optimize marking speed, depth, and quality based on specific material and application requirements.

High-Speed Operation

Designed for fast and efficient marking, the MOPA laser minimizes production time without compromising on quality. This ensures high throughput and boosts overall productivity in high-demand manufacturing environments.

Minimal Maintenance

Built for reliability, the MOPA laser marking machine requires minimal maintenance, reducing downtime and operational costs, making it a cost-effective solution for businesses focused on long-term efficiency.

Durable and Permanent Marks

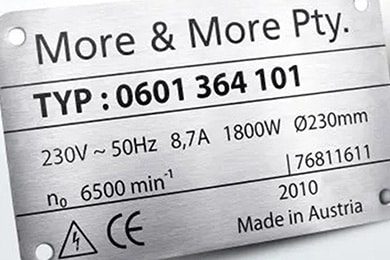

The high energy density of the MOPA laser creates deep, permanent marks that resist wear and tear, ensuring that engraved logos, serial numbers, and other identifiers remain clear and legible over time.

Comparison with Other Marking Methods

| Feature | MOPA Laser Marking Machine | Fiber Laser Marking | CO2 Laser Marking | Inkjet Printing |

| Precision | Extremely high precision with adjustable pulse control, ideal for fine details | High precision, but less flexible for intricate designs | Moderate precision, suitable for large areas or rough markings | Moderate precision, less detailed |

| Material Compatibility | Works on metals, plastics, ceramics, glass, and more | Primarily for metals, some plastics | Best for non-metals like wood, paper, and glass | Best for paper, cardboard, and plastics |

| Marking Speed | High-speed, minimal downtime, suitable for large-scale production | Fast marking speeds but with limited material flexibility | Slower compared to MOPA, not ideal for high-speed production | Slower marking speed, especially on large batches |

| Marking Quality | Delivers high-contrast, permanent, high-resolution marks | Produces durable marks but with less contrast on some materials | Marks are less durable and may fade over time | Marks are not permanent and can fade |

| Flexibility in Design | High flexibility with adjustable pulse settings, ideal for intricate designs | Limited by the nature of the laser pulse | Less customizable, suitable for basic designs | Very limited design capabilities, mainly for text or simple graphics |

| Energy Efficiency | Highly energy-efficient with low power consumption | Energy-efficient, though may require higher power for some materials | Less energy-efficient compared to MOPA | Less energy-efficient, uses more consumables |

| Operating Costs | Low operating costs with minimal consumables | Low operating costs, requires minimal maintenance | Higher costs due to consumables like gases and lenses | Higher costs for ink and regular maintenance |

| Maintenance | Low maintenance needs with minimal wear and tear | Low maintenance with occasional lens cleaning | Requires more maintenance, especially for optics | High maintenance, frequent ink replacement, and cleaning |

| Durability of Marks | Permanent, high-contrast, highly resistant to wear and environmental conditions | Durable but may lose contrast over on some metals | Less durable, susceptible to fading or wear | Marks are temporary and prone to fading or smudging |

| Marking Depth Control | Fine control over marking depth for various applications | Limited depth control | Can only mark shallow depths | No depth control, only surface printing |

| Application Versatility | Versatile for various industries including automotive, aerospace, electronics, jewelry, etc. | Best for industrial metal marking and engraving | Primarily used for non-metal applications | Primarily used for packaging and labeling |

| Cost-Effectiveness | Highly cost-effective for long-term use due to low consumables and maintenance | Cost-effective for specific industrial uses | Higher operating and consumable costs | Not cost-effective for large-scale production due to ink and maintenance costs |

Customer Reviews

Frequently Asked Questions

What Are MOPA Laser Marking Machines?

- Adjustable Pulse Duration: Unlike traditional fiber lasers, MOPA systems allow for fine control over the pulse width, which is the amount of time each pulse lasts. This flexibility enables the MOPA laser to achieve various marking effects, from very shallow, fine markings to deep engravings, depending on the application and material.

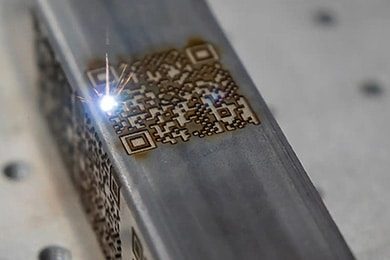

- High Precision and Detail: Due to the adjustable pulse duration, MOPA lasers can produce high-contrast and high-resolution markings, making them ideal for intricate designs, logos, serial numbers, barcodes, and other fine details. This is especially important for industries like electronics, automotive, and jewelry, where precision is critical.

- Versatility in Material Compatibility: MOPA laser marking machines can mark a wide range of materials, including metals (like stainless steel, aluminum, and titanium), plastics, ceramics, glass, and even some coatings. This makes them highly versatile for applications in industries such as electronics, aerospace, medical devices, and manufacturing.

- Durable and Permanent Marks: The MOPA laser creates permanent marks that are resistant to wear, fading, and corrosion. These marks can withstand harsh conditions such as exposure to chemicals, abrasion, and high temperatures, making them ideal for industries where durability and traceability are essential.

- Faster Marking Speeds: MOPA lasers are fast and efficient, enabling high-speed marking with minimal downtime, which is particularly advantageous for high-volume production environments.

- Low Maintenance: MOPA laser marking machines require minimal maintenance compared to other types of marking equipment. They have no consumables like ink or ribbons and typically have a long lifespan, contributing to lower operating costs over time.

What Materials Can MOPA Laser Marking Machines Mark?

- Metals: MOPA lasers are particularly effective on metals, offering high-contrast, permanent marks that are resistant to wear and corrosion. Some common metals marked by MOPA lasers include: Stainless Steel, Aluminum (including anodized aluminum), Titanium, Copper, Brass, Iron & Steel, Gold & Silver (commonly used in jewelry), Nickel

- Plastics: MOPA lasers can mark various plastic materials without damaging the surface. They are widely used for marking parts in the automotive, electronics, and consumer goods industries. Some common plastics marked by MOPA lasers include: ABS (Acrylonitrile Butadiene Styrene), PVC (Polyvinyl Chloride), Polycarbonate, PET (Polyethylene Terephthalate), Polypropylene, Polyethylene, Nylon, Acrylic

- Ceramics: MOPA lasers can engrave and etch ceramics with precision. This makes them suitable for applications in manufacturing, medical devices, and decorative items.

- Glass: MOPA lasers can create high-contrast markings on glass surfaces, such as logos, barcodes, and designs, without causing cracking or damage.

- Coatings & Paints: MOPA lasers are ideal for marking coated or painted surfaces, allowing you to remove or mark the coating while leaving the underlying material intact. This is particularly useful for marking parts with painted or anodized surfaces.

- Rubber: Rubber parts, used in automotive seals, gaskets, and other products, can be marked with MOPA lasers. The precision control helps to prevent excessive heat and material degradation.

- Textiles & Fabrics: MOPA lasers can engrave intricate designs, logos, and text on fabrics and textiles. They are commonly used in the fashion and apparel industries for branding and customization.

- Composites: MOPA lasers can mark composite materials, which are typically used in aerospace, automotive, and manufacturing sectors. These materials are often composed of a combination of fibers and resins.

- Wood & Bamboo: MOPA lasers are used to engrave or cut wood and bamboo, allowing for detailed and customized markings for items such as furniture, gifts, and decor.

- Food & Packaging Materials: MOPA lasers can be used to mark packaging materials such as plastics, paper, and foils. They are also used for food traceability, including engraving expiration dates and batch numbers.

How Accurate Are MOPA Laser Marking Machines?

- Fine Beam Quality: MOPA lasers typically deliver a beam with an M2 factor (beam quality) close to 1, which indicates an ideal, nearly perfect Gaussian beam profile. This leads to a smaller laser spot size, enabling precise and clean markings. With a spot size that can go as small as 20-30 microns, MOPA lasers are capable of creating intricate designs and fine details with high resolution. This is especially important in industries where precision is critical, such as electronics and jewelry.

- Adjustable Pulse Duration: One of the standout features of MOPA lasers is the ability to adjust the pulse width, which controls how long each laser pulse lasts. By varying the pulse duration, operators can fine-tune the marking process, allowing for minimal heat input and ensuring high-contrast, detailed marks on a range of materials. This helps achieve accurate engraving without causing excessive heat buildup or damaging the material.

- Minimal Thermal Impact: MOPA lasers generate shorter, controlled pulses compared to other types of lasers. This precise pulse control minimizes thermal impact, preventing excessive heat from affecting the surrounding material. The controlled heat input leads to sharp, clean marks that are particularly beneficial when marking delicate materials such as plastics, rubber, and coated metals.

- Repeatability: MOPA laser marking machines are known for their repeatable accuracy. Whether marking a single part or an entire production batch, the machine can maintain consistent quality and precision across multiple items. This is crucial for applications requiring the same design, serial numbers, or logos to be marked identically on every part. Repeatability is vital for mass production environments where quality control is essential.

- High Resolution and Fine Detailing: Thanks to the adjustable pulse duration and precise control over the beam, MOPA lasers can create extremely fine details, such as small text, QR codes, serial numbers, and complex logos. The laser system can etch tiny, intricate patterns with minimal distortion, making it ideal for applications requiring high-resolution markings.

- Accuracy in Diverse Materials: The precision of MOPA lasers is not limited to any specific material. Their adjustable settings make them highly versatile, and capable of marking hard metals, plastics, ceramics, glass, and more. For instance, MOPA lasers can produce high-contrast marks on anodized aluminum and stainless steel while preserving the integrity of delicate materials like rubber or wood.

What Is The Average Lifespan of MOPA Laser Marking Machines?

- Laser Source: The primary factor influencing the lifespan of MOPA laser marking machines is the fiber laser source. Fiber lasers generally last much longer than traditional laser sources. Under optimal conditions, they can operate for 20,000 to 30,000 hours before needing a replacement. The laser source’s lifespan is affected by usage intensity, operating power, and environmental factors.

- Maintenance and Care: Regular maintenance and proper care can extend the lifespan significantly. For example, ensuring that the machine’s cooling system is functioning properly, cleaning lenses, and calibrating the system as required can help avoid premature wear. Well-maintained machines can last longer than those operated under harsh or neglectful conditions.

- Operating Conditions: The environmental conditions in which the machine operates play a role. Machines used in clean, controlled environments last longer than those subjected to dust, humidity, or extreme temperatures. A harsh working environment can reduce the laser’s lifespan due to increased wear on internal components.

- Usage Frequency: The frequency and intensity of use also affect the machine’s longevity. Continuous, high-demand applications will naturally wear out the system more quickly. However, machines used intermittently or for lower-volume applications may last on the higher end of the lifespan spectrum.

- Quality of Components: The quality of individual components, such as laser diodes, optical fibers, and cooling systems, can impact how long the machine lasts. High-quality, well-constructed components will generally last longer than lower-quality alternatives.

What Power Options Are Available for MOPA Laser Marking Machines?

- Lower power options (20W to 60W) are ideal for marking lightweight materials such as plastics, rubber, and thin metals, providing high precision for detailed designs.

- Mid-range power options (100W to 120W) are more versatile, and capable of handling thicker metals, ceramics, and industrial-grade plastics, offering faster marking speeds and deeper engravings.

- High-power models (200W to 350W) are designed for heavy-duty, industrial applications that require deep, high-speed engraving on tough materials like stainless steel, titanium, and ceramics.

How Much Do MOPA Laser Marking Machines Cost?

- Power and Performance

- Lower Power Models (20W – 30W): These are generally priced between $3,000 and $6,000. They are suitable for marking lightweight materials like plastics, rubber, and thin metals.

- Mid-Range Power Models (50W – 100W): Typically priced between $6,000 and $9,000, these machines offer greater versatility and are suitable for a broader range of materials, including thicker metals and more demanding applications.

- High Power Models (200W and above): Machines with higher power capabilities, usually priced from $10,000 to $13,000, are designed for high-speed, high-volume production and can mark tougher materials, such as stainless steel, titanium, or ceramics.

- Brand and Quality

- Reputable Brands: Established manufacturers like Raycus, IPG Photonics, and Maxphotonics tend to offer machines on the higher end of the price spectrum. These brands often come with superior customer service, warranties, and high-quality components.

- Less Known or Budget Brands: Machines from lesser-known manufacturers can be more affordable, often within the lower end of the price range. However, they may offer fewer features or shorter lifespans.

- Features and Customization

- Basic Features: Basic models with standard laser marking capabilities and smaller working areas typically cost less, while more advanced features (e.g., auto-focus, rotary attachments, large working areas, or enhanced software) can increase the price.

- Custom Configurations: Tailored solutions based on specific requirements (e.g., for particular industries, or integration into production lines) can also push prices toward the higher end.

- Additional Costs

- Keep in mind that the base price doesn’t always include other expenses like installation fees, training, maintenance contracts, or spare parts. Operational costs (e.g., electricity, cooling, consumables) can also affect long-term costs.

What Are The Limitations of MOPA Laser Marking Machines?

- High Cost: MOPA lasers are generally more expensive than traditional fiber lasers. The added cost is due to the advanced technology used to achieve more precise and adjustable pulse control. This higher upfront cost can make MOPA laser marking machines less accessible for smaller businesses or those with limited budgets.

- Complexity in Operation: Operating MOPA laser marking machines requires a certain level of expertise. The adjustable pulse duration and frequency settings offer more flexibility, but they also introduce complexity in finding the right configuration for different materials. Users may need to undergo specialized training or rely on expert operators to fully utilize the system’s capabilities.

- Limited Material Compatibility: While MOPA lasers can mark a wide range of materials, their performance may not be as optimal on certain types of metals or very hard materials. For instance, MOPA lasers can struggle with materials that require extremely high power for deep engraving or marking, such as hardened steels or certain ceramics.

- Lower Marking Speed: While MOPA lasers are capable of high-quality marking, their speed is generally slower compared to some other laser types, especially when performing deep engraving. The process of fine-tuning parameters like pulse duration and frequency can slow down the marking process when compared to the speed of standard fiber lasers.

- Limited Depth Control: MOPA lasers are ideal for high-quality surface marking, but they are not designed for deep engraving. While they can control the surface heat to create fine markings, achieving significant depth in materials like metals may require additional processing time or different laser technologies.

- Thermal Damage Risk: Although MOPA lasers can be finely tuned to minimize thermal damage, there is still a risk of unwanted heat-affected zones (HAZ), especially on heat-sensitive materials. Careful adjustment of parameters is required to prevent thermal distortion, discoloration, or burning of materials.

- Cooling Requirements: MOPA laser marking machines typically require robust cooling systems to prevent overheating, especially when used for long periods. This adds another layer of maintenance and operational costs. Inadequate cooling can reduce the lifespan and efficiency of the laser.

- Maintenance and Durability: Like any advanced laser system, MOPA lasers require regular maintenance to ensure optimal performance. The laser diodes, optics, and cooling systems may require periodic checks, repairs, and replacements. This maintenance cost and effort can add to the overall operational expense.

- Size and Weight: MOPA laser marking machines are often larger and heavier compared to simpler laser systems. This makes installation more challenging and can also limit the mobility of the system. In environments where space is limited or portability is required, this can be a constraint.

- Limited Color Control: While MOPA lasers are known for their ability to create a range of surface finishes and fine details, controlling specific colors (such as those seen in anodized aluminum or stainless steel) can still be challenging. The results can depend on the material, but the color variation may not always meet specific expectations, especially for applications that require precise color control.

How to Maintain MOPA Laser Marking Machines?

- Regular Cleaning

- Laser Lens and Mirrors: Dust and debris can accumulate on the laser optics, reducing the system’s efficiency and marking quality. Clean the lenses, mirrors, and other optical components using specialized lens wipes or a soft, lint-free cloth. For more stubborn dirt, use optical-grade cleaning solutions.

- Air Filters: Many MOPA laser systems have air filters that prevent dust from entering the system and affecting performance. Check the filters regularly and clean or replace them if necessary. Clean filters help prevent overheating and maintain consistent airflow, which is crucial for cooling.

- Fan and Heat Sink: The cooling fans and heat sinks in MOPA laser machines help dissipate heat. Over time, dust and particles may accumulate, blocking airflow. Clean the fans and heat sinks regularly to avoid overheating and ensure efficient cooling.

- Cooling System Maintenance

- Check Water Cooling System (if applicable): Some MOPA lasers use a water cooling system to maintain the optimal temperature. Ensure that the water is clean, and the system is free of air bubbles. Replace the cooling fluid according to the manufacturer’s recommendations. Clean the cooling pipes and check for any leaks or blockages.

- Monitor Temperature: MOPA lasers generate a significant amount of heat during operation, so it’s essential to monitor the system’s temperature. Ensure that the cooling system is functioning properly and that the machine is not overheating. High temperatures can lead to degraded performance or damage to sensitive components.

- Inspect Laser Source

- Check Diode Performance: The laser diode is the heart of the MOPA system, and its longevity directly impacts the laser’s performance. Regularly check the laser output power to ensure it’s operating within specifications. If the power drops significantly or unevenly, it may indicate that the diode needs servicing or replacement.

- Monitor Pulse Quality: Since MOPA lasers are known for their adjustable pulse width and frequency, it’s important to monitor the pulse quality over time. A decrease in pulse energy or inconsistency in pulse delivery can indicate an issue with the laser source or optics.

- Calibration and Alignment

- Optical Alignment: Regularly check and calibrate the optical alignment to ensure the laser beam is correctly focused and aligned with the marking area. Misalignment can lead to reduced marking quality and increased wear on components.

- Laser Focusing: The laser focus needs to be adjusted for optimal marking. Regularly inspect the focus lens and ensure the focal length is set correctly for different materials. Misfocus can lead to poor quality marks and slower marking speeds.

- Check the Control System

- Software Updates: Keep the software up to date to ensure the latest features, optimizations, and bug fixes are applied. Many MOPA laser systems are controlled via specialized software, which may receive updates to improve performance or add new features.

- System Diagnostics: Perform regular system diagnostics to ensure the laser, control board, and other components are working correctly. If the machine has a built-in diagnostic feature, use it to check for any irregularities or faults in the system.

- Inspect and Replace Consumables

- Replace Consumables: Over time, consumables such as lenses, focusing mirrors, and other optical components may wear out or degrade. Inspect these components regularly and replace them as needed. Follow the manufacturer’s guidelines for replacement intervals.

- Check the Laser Lens Cover: Some MOPA laser systems use lens covers that can become dirty or damaged over time. Inspect and replace these covers to protect the lenses and maintain the system’s efficiency.

- Monitor Electrical Components

- Inspect Power Supply: Regularly check the power supply to ensure it’s stable and not fluctuating. Power surges or instability can damage sensitive components in the laser system. Ensure all connections are secure, and cables are in good condition.

- Cooling Fans for Electronics: The electronics that drive the MOPA laser require cooling fans to prevent overheating. Make sure that these fans are clean and operational, and provide adequate airflow.

- Environmental Control

- Temperature and Humidity: Ensure the environment in which the MOPA laser is operated is within the recommended temperature and humidity ranges. Extreme conditions can negatively affect performance and the longevity of components.

- Clean Environment: Keep the work area clean and free of excessive dust or debris. Dust particles can damage sensitive optics and affect the quality of the laser marks.

- Perform Regular Functional Tests

- Test Marks: Periodically perform test marks on different materials to ensure that the system is producing consistent and high-quality results. This can help detect early signs of performance degradation or component failure.

- Check Power Output: Test the power output at regular intervals to ensure it’s within the acceptable range. A significant drop in power may indicate an issue with the laser source or optics.

- Follow the Manufacturer’s Guidelines

- Always refer to the manufacturer’s maintenance manual for specific maintenance schedules, part replacement intervals, and troubleshooting tips. This can help you avoid potential issues and extend the life of your MOPA laser marking system.

Related Resources

2026 Best CO2 Laser Cutter for Small Business

Laser Marking VS Screen Printing

Laser Welding VS MIG Welding

Laser Rust Removal VS Sandblasting Rust Removal

Contact Us

Contact Information Form: