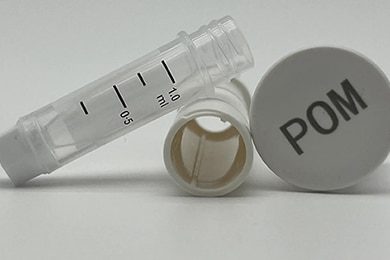

CO2 laser marking offers exceptional precision, allowing for intricate designs, logos, barcodes, and serial numbers to be marked with extreme accuracy, ensuring clear and legible results on a variety of materials.

The markings produced by CO2 laser machines are permanent, and resistant to fading, wear, and corrosion, making them ideal for long-lasting product identification and traceability in demanding environments.

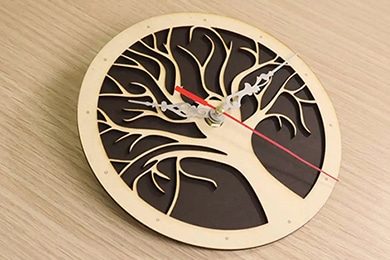

CO2 lasers can mark a wide range of materials, including plastics, wood, ceramics, and more, making them versatile solutions for various industries and applications.

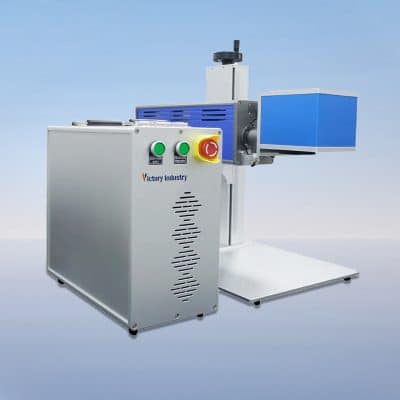

CO2 laser marking machines are known for their low maintenance requirements, reducing downtime and long-term operational costs while delivering reliable performance over extended periods.

These machines operate at high speeds, improving productivity in both small-scale and high-volume production settings, and allowing for efficient processing of large quantities of parts.

CO2 laser marking is a non-contact process that produces minimal waste, requires no consumables like inks or chemicals, and generates less heat, making it an eco-friendly choice for sustainable manufacturing.

| Feature | CO2 Laser Marking | Thermal Transfer Printing | Inkjet Marking | Chemical Etching |

| Precision | Extremely high precision, suitable for fine details and intricate designs | High precision but limited to specific materials like labels | Moderate precision, best for larger characters or logos | Moderate precision, can achieve good results on flat surfaces |

| Material Compatibility | Works on metals, plastics, glass, wood, ceramics, and more | Limited to materials like synthetic labels or films | Works well on porous materials like paper, plastics, and some metals | Works best on metals, particularly stainless steel and aluminum |

| Durability of Marking | Permanent, resistant to fading, wear, and corrosion | Durable but can fade over time or under exposure | Marks can fade or smudge, not as durable as laser marking | Highly durable but requires post-process for protective coating |

| Maintenance | Low maintenance, no consumables except electricity | Requires ribbons and regular maintenance | Requires ink and frequent printhead cleaning | Requires chemical solutions, can be labor-intensive |

| Speed | High-speed operation, ideal for both small and large batches | Moderate speed, often slower than laser marking | High-speed operation for large volumes but lower precision | Slow process, typically batch-oriented |

| Cost of Operation | Low cost per marking, minimal consumables | Moderate cost due to ribbon usage and maintenance | Higher cost due to ink usage and frequent printhead replacements | High initial setup cost, ongoing chemical costs |

| Environmental Impact | Eco-friendly, minimal waste, no chemicals or inks | Minimal waste, but uses consumables that need disposal | Generates ink waste, can involve chemicals and solvents | Environmental impact due to chemicals used for etching |

| Customization Flexibility | Excellent for logos, serial numbers, barcodes, and detailed designs | Good for high-volume, pre-defined designs and barcodes | Suitable for logos, barcodes, and large characters | Best for simple designs, limited flexibility |

| Setup Time | Quick setup, minimal adjustments required | Quick setup for labeling, no complex adjustments | Quick setup, but requires ink refills or replacements | Slow setup, requires chemical preparation and cleaning |

| Cost of Equipment | Moderate initial cost, long-term low operational cost | Moderate initial cost, ribbon refills required | Lower initial cost, higher ink and maintenance costs | High initial cost due to chemical handling and safety |

Contact Information Form:

Copyright © 2025 Victory Industry Inc. All rights reserved.