Introduction

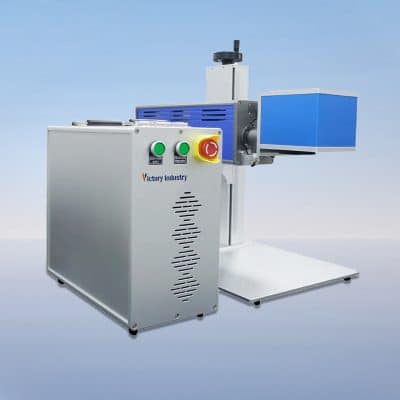

Laser Marking Machines

-

VIM-FD Laser Marking Machine

Rated 4.75 out of 5$2,000.00 – $20,000.00Price range: $2,000.00 through $20,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-FH Laser Marking Machine

Rated 4.75 out of 5$2,200.00 – $20,200.00Price range: $2,200.00 through $20,200.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-FS Laser Marking Machine

Rated 4.50 out of 5$2,300.00 – $20,300.00Price range: $2,300.00 through $20,300.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-FP Laser Marking Machine

Rated 5.00 out of 5$2,100.00 – $20,100.00Price range: $2,100.00 through $20,100.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-FE Laser Marking Machine

Rated 4.75 out of 5$2,750.00 – $20,750.00Price range: $2,750.00 through $20,750.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-FF Laser Marking Machine

Rated 4.50 out of 5$3,500.00 – $21,500.00Price range: $3,500.00 through $21,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-MD Laser Marking Machine

Rated 5.00 out of 5$3,000.00 – $13,000.00Price range: $3,000.00 through $13,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-CD Laser Marking Machine

Rated 4.75 out of 5$2,000.00 – $11,500.00Price range: $2,000.00 through $11,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-CS Laser Marking Machine

Rated 5.00 out of 5$2,500.00 – $12,000.00Price range: $2,500.00 through $12,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-CP Laser Marking Machine

Rated 4.75 out of 5$2,200.00 – $11,700.00Price range: $2,200.00 through $11,700.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIM-CF Laser Marking Machine

Rated 5.00 out of 5$3,500.00 – $13,000.00Price range: $3,500.00 through $13,000.00 Select options This product has multiple variants. The options may be chosen on the product page

Applications

Advantages of Laser Marking

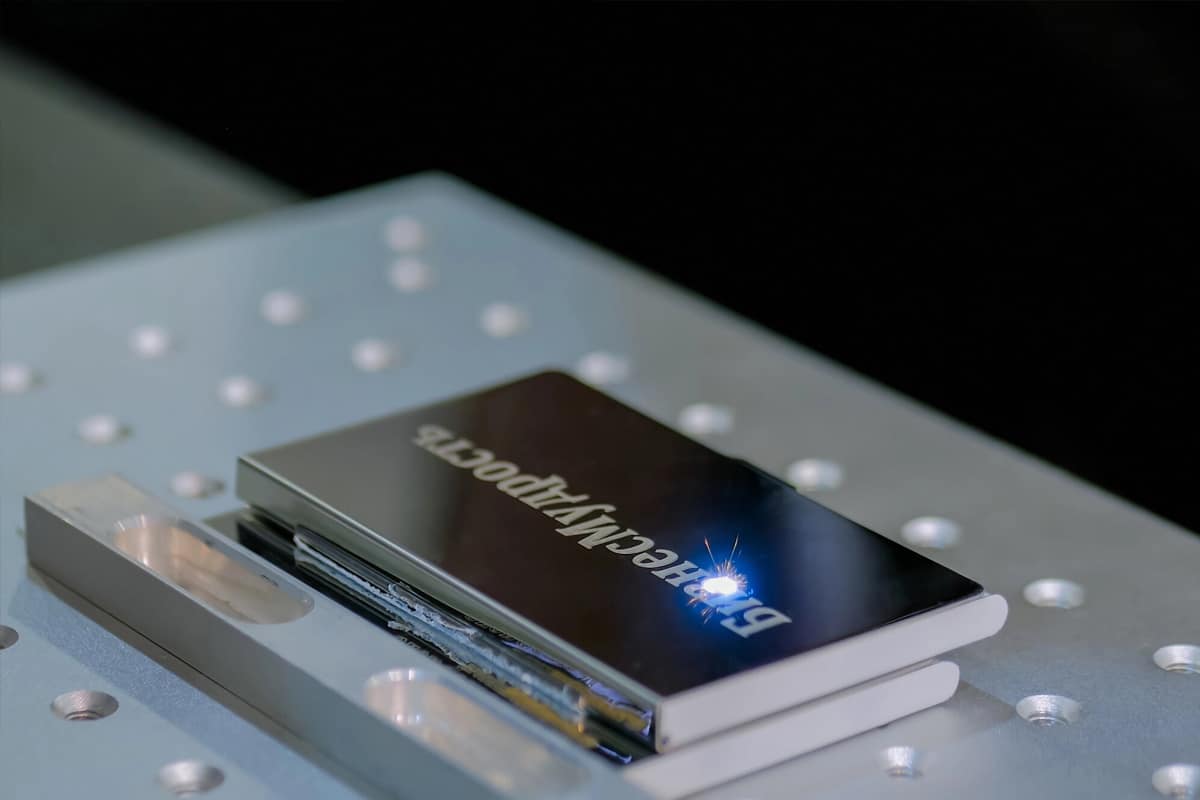

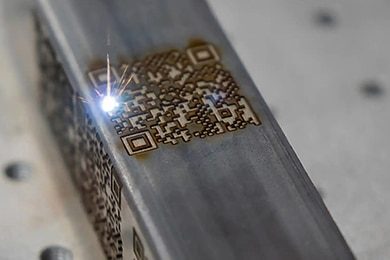

Exceptional Precision

Laser marking provides unmatched accuracy, allowing for fine, intricate designs and text to be marked with high resolution. This ensures consistent quality and clarity, even on complex surfaces or small components.

Durable and Permanent Marks

Laser markings are highly resistant to wear, fading, and corrosion. The marks are permanent, making them ideal for applications where longevity and traceability are essential, such as serial numbers or regulatory codes.

Eco-Friendly Process

Laser marking is an environmentally friendly method, requiring no inks, chemicals, or solvents. It reduces waste and the need for consumables, aligning with sustainable practices while cutting operational costs.

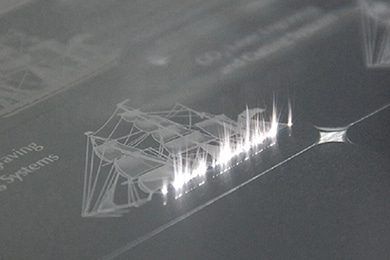

Versatile Material Compatibility

Laser marking can be applied to a wide range of materials, including metals, plastics, ceramics, and glass. This versatility makes it suitable for diverse industries, from manufacturing to medical and automotive sectors.

Non-Contact Technology

As a non-contact process, laser marking eliminates the risk of damaging the material surface. This is especially beneficial for delicate or soft materials, preserving product integrity while ensuring precise marks.

High-Speed and Efficiency

Laser marking machines operate quickly and efficiently, making them ideal for high-volume production lines. The speed of operation reduces downtime and increases overall throughput, boosting productivity in fast-paced environments.

Comparison with Other Marking Methods

| Feature | Laser Marking | Inkjet Marking | Chemical Etching | Mechanical Engraving |

| Precision | High precision, capable of intricate details | Moderate precision, less fine detail | High precision, but often less detailed | High precision, but limited to material hardness |

| Durability | Permanent, highly durable, resistant to wear, chemicals, and heat | Fades over time, sensitive to abrasion | Permanent, but can be less consistent over time | Permanent, may wear with excessive use |

| Material Compatibility | Works on metals, plastics, ceramics, glass, and more | Works primarily on porous surfaces like paper and plastics | Best for metals, ceramics, and glass | Primarily works on hard metals and plastics |

| Eco-Friendliness | Environmentally friendly, no need for inks or chemicals | Uses ink and solvents, not eco-friendly | Uses chemicals, hazardous waste generated | No chemicals but produces metal shavings |

| Speed | Very fast, suitable for high-volume production | Moderate speed, typically slower than laser | Slow, time-consuming process | Slow, especially on complex designs |

| Cost | Higher initial cost, low operating cost | Low initial cost, higher operational cost | High initial setup cost, ongoing chemical costs | Moderate initial cost, high tool wear costs |

| Surface Impact | Non-contact, no surface damage | Can cause smudging or fading over time | Chemical reaction may slightly alter surface | Contact-based, causes wear on surfaces |

| Maintenance | Low maintenance, minimal wear | Requires regular ink refills and cleaning | Requires handling and disposal of chemicals | High maintenance, tool wear needs replacement |

| Marking Complexity | Can create complex patterns, text, logos, and graphics | Suitable for simple text and basic graphics | Suitable for detailed designs but slower | Can engrave detailed designs but limited by material |

| Flexibility in Production | Highly flexible, scalable for any production size | Best for low-volume or variable production | Ideal for custom, low-volume etching | Best for small-scale, custom, or high-precision work |

Customer Reviews

Frequently Asked Questions

What Are Laser Marking Machines?

How High Is The Accuracy of Laser Marking Machines?

What Are The Powers of Laser Marking Machines?

- Fiber Laser Marking Machines: These machines are available in multiple power configurations. The 20W model is ideal for light marking on metals and plastics. For faster marking with slightly deeper results, the 30W model is an excellent choice. The 50W model offers deeper engravings, while the 60W model provides more power for heavy-duty tasks. For marking thicker materials, the 70W model is optimal. The 100W model delivers the deepest and fastest markings, making it perfect for high-volume, high-precision applications.

- CO2 Laser Marking Machines: Best suited for non-metallic materials, CO2 lasers also come in various power levels. The 30W model is perfect for marking wood, glass, and other non-metal materials. For faster marking, the 40W model is effective, while the 60W model offers deeper markings. The 100W model is ideal for engraving deeper on non-metals, and the 150W model provides the highest power for the most demanding marking tasks.

- MOPA Laser Marking Machines: Known for their flexibility and versatility, MOPA lasers are available in a range of power options. The 20W model is great for detailed markings on metals and plastics, while the 30W model is suited for faster, deeper engravings. The 60W model can handle tougher jobs with ease, and the 100W model is perfect for fast and deep marking. For larger or more complex tasks, the 120W model offers strength and reliability. For deep engravings on tough materials, the 200W model excels, and the 350W model is designed for the most demanding marking applications, offering extreme power and performance.

What Is The Price of Laser Marking Machines?

- Fiber Laser Marking Machines: These machines are commonly used for marking metals and some plastics. Prices typically range from $2,500 to $25,000, with variations depending on the machine’s power (ranging from 20W to 100W) and specific capabilities, such as speed, precision, and customization options.

- CO2 Laser Marking Machines: Ideal for marking non-metallic materials like wood, glass, and acrylic, CO2 lasers generally cost between $3,000 and $20,000. The price is influenced by the power (usually from 30W to 150W) and additional features such as speed, engraving depth, and system integration.

- MOPA Laser Marking Machines: Known for their adjustable pulse durations, MOPA lasers are versatile for marking metals and plastics with fine details. Prices for MOPA machines typically range from $3,500 to $15,000, depending on the power level (20W to 350W) and the complexity of the tasks they can handle.

How To Maintain Laser Marking Machines?

- Regular Cleaning

- Laser Lens: Clean the laser lens regularly using a soft, lint-free cloth and an appropriate cleaning solution. This prevents dust and debris from affecting the laser’s accuracy and power.

- Cooling System: For machines with a water cooling system, ensure the coolant is clean and replaced as recommended by the manufacturer. Regularly check the water level and clean the cooling fan or radiator to prevent overheating.

- Machine Surface: Clean the exterior of the machine frequently to remove dust, dirt, and debris, ensuring both performance and safety are maintained.

- Check and Replace Parts

- Laser Source: Monitor the performance of the laser source and replace it when its output power noticeably decreases. Regular checks help spot potential issues before they impact your work.

- Filters: If your machine has air filters, replace them regularly to ensure proper airflow and prevent dust buildup.

- Belts and Rails: Inspect belts, rails, and other moving components for wear. Lubricate them as needed and replace any worn parts to ensure smooth operation.

- Software and Firmware Updates

- Software Maintenance: Keep the machine’s software up to date for optimal performance, compatibility with other systems, and access to the latest features.

- Calibration: Calibrate the machine periodically to maintain high precision and consistency. Follow the manufacturer’s recommended calibration schedule.

- Environmental Control

- Humidity and Temperature: Operate the machine in a controlled environment with stable temperature and humidity levels. Excess moisture or extreme temperatures can damage the machine’s components.

- Ventilation: Ensure the machine is placed in a well-ventilated area to prevent overheating. Good ventilation also helps to dissipate fumes and particles generated during marking.

- Routine Inspections

- Safety Systems: Regularly inspect safety features like emergency stop buttons and interlock systems to ensure proper function.

- Electrical Connections: Check all electrical connections for signs of wear or looseness, which can cause malfunctions or safety risks.

- Preventive Maintenance Schedule

- Follow the manufacturer’s preventive maintenance schedule for specific instructions on when and how to perform maintenance tasks. This ensures your machine runs efficiently over time.

- Professional Servicing

- Consider professional servicing periodically, especially for machines in heavy use or demanding environments. A technician can identify issues early, ensuring the longevity and reliability of your machine.

What Are The Disadvantages of Laser Marking Machines?

- High Initial Cost: Laser marking machines, especially those with advanced features or higher power levels, come with a significant upfront cost. This can be a barrier for small businesses or startups with limited budgets.

- Material Limitations: Different types of lasers are suited to different materials. For instance, fiber lasers are primarily used for metals and some plastics, while CO2 lasers are more effective on non-metals. This specialization often means needing multiple machines for various materials, which can increase overall costs.

- Complex Operation and Setup: While laser marking machines are generally user-friendly, the setup process can be complex, especially for custom applications. Operators may require specialized training to optimize the machine for specific tasks, adding time and cost to the operation.

- Maintenance Requirements: Though laser marking machines require less maintenance than other marking methods, they still need regular cleaning, calibration, and part replacements. Ignoring maintenance can lead to reduced performance or costly repairs over time.

- Potential Safety Risks: Laser machines use high-intensity beams, which can be hazardous if proper safety protocols are not followed. Operators must wear protective gear, such as laser safety glasses, and ensure that the machine operates in a controlled, safe environment.

- Energy Consumption: High-power lasers can consume considerable energy, especially during continuous or high-intensity operations. This can lead to increased energy costs, making it a less economical choice for some operations.

- Limited Depth of Marking: Laser marking is excellent for surface-level designs but may not be suitable for deep engraving or cutting applications. For tasks requiring significant material removal, other technologies may be needed, adding complexity to the process.

- Environmental Considerations: Certain materials, such as plastics or coated metals, can produce harmful fumes and particles during laser marking. Proper ventilation and filtration systems are essential to ensure a safe working environment and minimize environmental impact.

- Upfront Learning Curve: New operators may face a learning curve in understanding the machine’s capabilities, software settings, and best practices for different materials. This can slow down production initially and require additional time for staff training.

What Is The Service Life of Laser Marking Machines?

- Fiber Laser Marking Machines

- Service Life: Fiber lasers are renowned for their durability, with a typical service life ranging from 50,000 to 100,000 hours of operation. This longevity is due to their solid-state design, which has fewer moving parts and greater resistance to wear.

- CO2 Laser Marking Machines

- Service Life: CO2 lasers generally last 20,000 to 30,000 hours. While they are still reliable, the laser tube in these machines tends to require replacement after several thousand hours, making them more maintenance-intensive than fiber lasers.

- MOPA Laser Marking Machines

- Service Life: MOPA lasers, which are a variation of fiber lasers with adjustable pulse durations, also offer long lifespans similar to standard fiber lasers, ranging from 50,000 to 100,000 hours.

- Factors Affecting Service Life

- Operating Conditions: Machines used in harsh environments or under heavy continuous loads tend to have shorter service lives.

- Maintenance: Regular maintenance, including cleaning, calibration, and part replacement, can extend the life of a laser marking machine significantly.

- Usage: The frequency and intensity of use influence the overall lifespan. Machines used intermittently and well-maintained can last longer than those subjected to continuous, high-intensity production.

What Training Is Required to Operate Laser Marking Machines?

- Basic Machine Operation

- Understanding Controls: Operators should be familiar with the machine’s basic controls, such as the power, speed, and focus settings.

- Loading and Positioning Materials: Training on how to securely position materials and adjust the working area for accurate marking.

- Software Interface: Learning how to operate the software that communicates with the machine, including designing or uploading files for marking.

- Laser Safety Training

- Laser Safety Protocols: Operators must understand the risks associated with high-intensity lasers, including eye safety and the use of protective eyewear.

- Personal Protective Equipment (PPE): Training on wearing appropriate PPE, such as goggles, gloves, and protective clothing.

- Emergency Procedures: Knowing how to handle emergencies, such as machine malfunctions or fires, and understanding the emergency stop functions.

- Material Handling and Marking Process

- Material-Specific Marking: Understanding the specific requirements for different materials (metals, plastics, wood, etc.) to adjust settings like power and speed.

- Adjusting Marking Parameters: Training on how to fine-tune laser settings based on material thickness, desired mark depth, and engraving detail.

- Cooling System Maintenance: Operators should be trained to maintain cooling systems to ensure optimal machine performance and prevent overheating.

- Machine Maintenance and Troubleshooting

- Routine Maintenance: Operators should learn how to clean the laser lens, replace filters, and check for wear on moving parts.

- Basic Troubleshooting: Training on how to identify and solve common issues like power loss, software malfunctions, or laser beam misalignment.

- Software Updates: Operators need to know how to update the machine’s firmware and software to maintain compatibility and functionality.

- Quality Control and Calibration

- Marking Quality Control: Training in inspecting marks for quality, ensuring they meet the required standards for clarity, depth, and precision.

- Calibration: Operators must know how to regularly calibrate the machine to ensure it maintains high precision.

- Safety Regulations and Compliance

- Regulatory Compliance: Knowledge of the safety standards and regulations governing laser equipment operation in different industries.

- Environmental Considerations: Understanding the safety protocols for venting fumes and maintaining a safe working environment.

- Advanced Features and Techniques (Optional)

- Advanced Software Features: For operators using more complex machines, training on advanced design tools, and automation features in the software.

- Multi-Layer Marking: For advanced applications that require multi-layer engraving or intricate designs.

Related Resources

Best Laser Cleaning Machines for Rust Removal in 2026

CNC Punching Machine vs Laser Cutting: Which Is Best?

2026 Best CO2 Laser Cutter for Small Business

Laser Marking VS Screen Printing

Contact Us

Contact Information Form: