Introduction

Continuous Laser Cleaning Machines

-

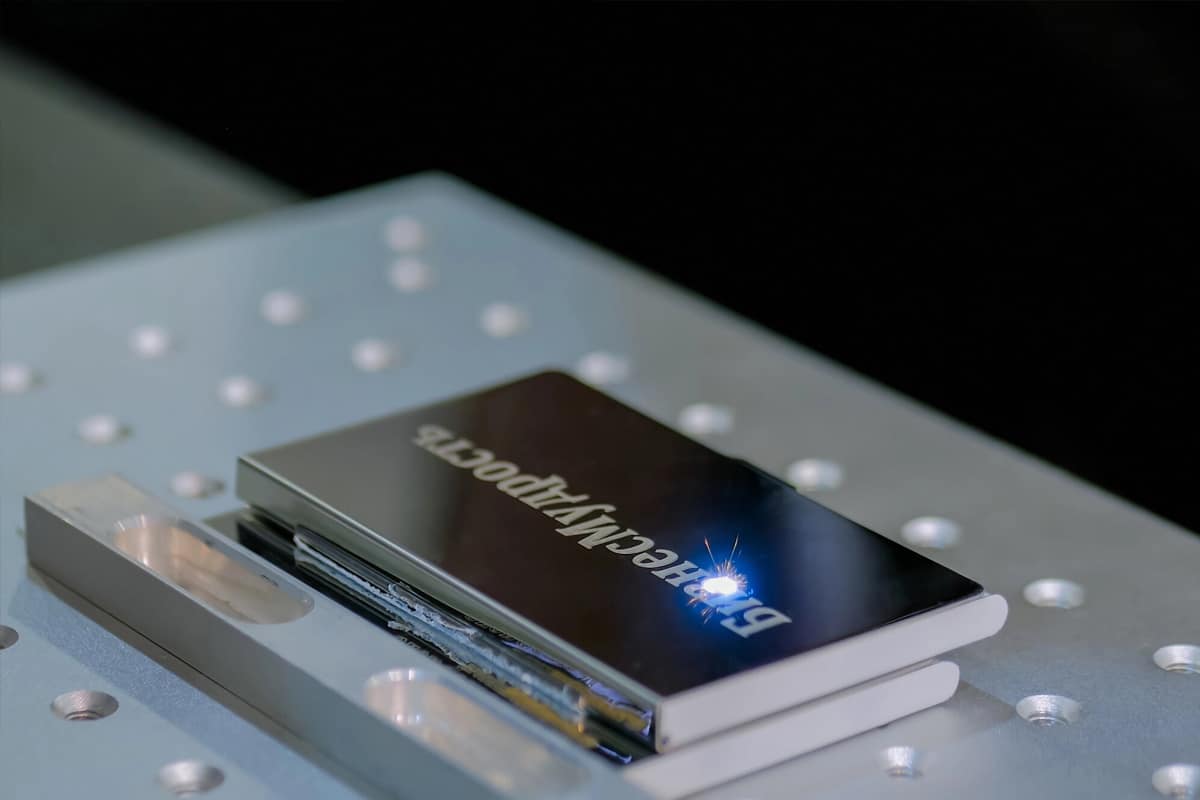

VIQ Laser Cleaning Machine

Rated 4.75 out of 5$3,800.00 – $8,400.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIQ-P Laser Cleaning Machine

Rated 5.00 out of 5$3,700.00 – $8,300.00 Select options This product has multiple variants. The options may be chosen on the product page

Applications

Advantages of Laser Cleaning

Eco-Friendly Technology

Laser cleaning eliminates the need for harsh chemicals or abrasives, reducing environmental impact and minimizing waste. It offers a sustainable solution that aligns with green manufacturing practices.

Non-Contact Cleaning

The non-contact nature of laser cleaning prevents any wear or damage to surfaces, ensuring a gentle yet thorough cleaning process that preserves the integrity of the material being cleaned.

High Precision and Efficiency

Laser cleaning provides precise control over the cleaning process, enabling the removal of contaminants with high accuracy, while also reducing the time and effort compared to traditional cleaning methods.

Minimal Maintenance

With fewer moving parts and no consumables like abrasive media, Continuous Laser Cleaning Machines require minimal maintenance, lowering operational costs and increasing machine lifespan.

Safe and Hazard-Free

The process is safe for operators, as it eliminates the need for toxic chemicals, solvents, or abrasive materials, contributing to a safer and healthier work environment.

Versatile for Various Applications

Suitable for cleaning a wide range of materials and surfaces, laser cleaning machines adapt to different industries, making them ideal for tasks like rust removal, paint stripping, and surface preparation.

Comparison with Other Cleaning Methods

| Cleaning Method | Continuous Laser Cleaning | Abrasive Blasting | Chemical Cleaning | Ultrasonic Cleaning |

| Efficiency | High precision and speed, ideal for continuous operation | Effective for heavy-duty cleaning, but can be slower | Fast for specific contaminants, but less precise | High precision for small parts, slower for large items |

| Environmental Impact | Eco-friendly, no chemicals, minimal waste | Generates dust and waste, harmful to the environment | Toxic chemicals and waste, harmful to the environment | Uses water and chemicals, potential waste generation |

| Cost | Low long-term operational costs | High operational costs due to media usage | Medium to high due to chemicals and disposal | Medium cost for consumables and water |

| Maintenance | Minimal, no abrasive media required | Frequent maintenance of equipment | Requires regular chemical replenishment | Requires periodic maintenance of ultrasonic equipment |

| Safety | Safe, no hazardous chemicals | The risk of airborne particles requires protective gear | Exposure to toxic substances requires protective gear | Safe, but requires controlled handling of solutions |

| Cleaning Speed | Fast, ideal for large and continuous cleaning tasks | Moderate, slower for intricate tasks | Moderate, ideal for certain substances like oils | Slow for large objects, ideal for small or intricate parts |

| Versatility | Highly versatile across various industries | Limited to robust surfaces and tough contaminants | Limited versatility, often specific to certain contaminants | Best for small, delicate parts, not large surfaces |

| Surface Suitability | Suitable for metals, composites, ceramics | Suitable for metals, concrete, stone | Suitable for delicate materials, specific contaminants | Ideal for metals, plastics, glass, and ceramics |

Customer Reviews

Frequently Asked Questions

How Do Continuous Laser Cleaning Machines Work?

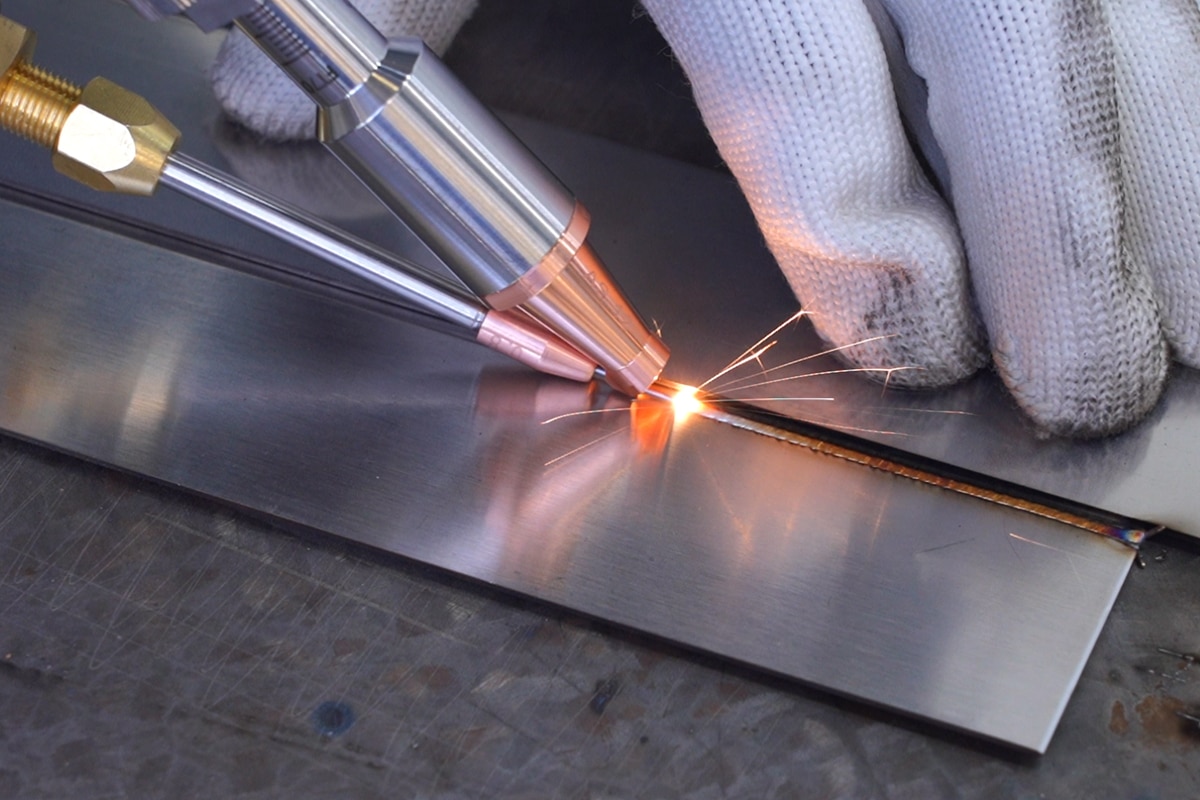

- Laser Emission: The machine generates a high-powered laser beam that is directed at the surface to be cleaned. The laser’s energy is absorbed by contaminants like rust or paint, causing them to vaporize or break apart.

- Surface Interaction: When the laser hits the surface, it heats the target material (e.g., rust or paint) to a point where it undergoes rapid thermal expansion, which either burns off or removes the unwanted layer. The laser beam is precisely controlled to ensure that only the contaminants are affected, leaving the underlying material intact.

- Continuous Operation: Unlike some other laser cleaning methods, continuous laser cleaning machines can operate continuously for long periods, making them ideal for high-demand or industrial environments. The machine’s motion system ensures the laser beam moves across the surface, cleaning large areas quickly.

- Fume Extraction: As the laser interacts with contaminants, it produces fumes and particulate matter. Most continuous laser cleaning machines come equipped with fume extraction systems that capture and filter these byproducts, maintaining a clean and safe working environment.

- Control and Flexibility: These machines often feature adjustable settings for laser power, speed, and focus, allowing operators to tailor the cleaning process based on the material and surface condition. This level of control ensures precision and efficiency, even with delicate components.

- Eco-Friendly Process: One of the key advantages of laser cleaning is its environmentally friendly nature. The process does not require abrasive materials or toxic chemicals, and it generates minimal waste, making it a sustainable choice for surface cleaning.

What Is The Power of Continuous Laser Cleaning Machines?

- 1000W: Ideal for light-duty cleaning tasks such as removing thin layers of rust, paint, or oil. Suitable for delicate surfaces and precision cleaning applications.

- 1500W: Offers enhanced cleaning capability, perfect for small to medium-scale cleaning jobs with moderate contaminants.

- 2000W: A versatile option for medium to heavy cleaning tasks, balancing speed and precision. Effective for tougher contaminants and larger surface areas.

- 3000W: Designed for industrial-grade cleaning, capable of removing thick rust, coatings, and heavy contaminants quickly and efficiently.

- 6000W: The most powerful option, ideal for large-scale and high-demand applications. It delivers maximum cleaning speed and performance for the toughest surfaces and industrial environments.

What Is The Price of Continuous Laser Cleaning Machines?

- 1000W Laser Cleaning Machine: $4,900. Ideal for light-duty cleaning applications, offering precise and efficient removal of contaminants on delicate surfaces.

- 1500W Laser Cleaning Machine: $5,000. Suitable for small to medium cleaning tasks, providing a balance of power and cost-effectiveness for general cleaning needs.

- 2000W Laser Cleaning Machine: $6,500. This model provides more power for cleaning tougher contaminants, ideal for medium-scale operations and versatile applications.

- 3000W Laser Cleaning Machine: $8,000. A high-performance option, perfect for industrial-scale cleaning of larger areas or more challenging contaminants like heavy rust or thick coatings.

- 6000W Laser Cleaning Machine: $12,500. The most powerful option is designed for high-demand environments that require maximum efficiency and speed, such as large-scale industrial or heavy-duty cleaning.

What Is The Power Consumption of Continuous Laser Cleaning Machines?

- 1000W Laser Cleaning Machine: Consumes 4.5-5 kW of power, making it an energy-efficient option for light-duty tasks. It’s perfect for applications where precision is key but energy efficiency is also a priority.

- 1500W Laser Cleaning Machine: This model typically consumes 6-7 kW, offering a good balance of power and energy use. It is ideal for small to medium-scale cleaning operations, delivering high performance while keeping energy consumption manageable.

- 2000W Laser Cleaning Machine: With a power consumption of 8-9 kW, this machine is suited for medium to heavy-duty tasks. It efficiently handles tougher contaminants, providing robust cleaning capabilities while maintaining reasonable energy efficiency.

- 3000W Laser Cleaning Machine: Consuming 12-13 kW, this model is designed for industrial-scale cleaning. Its high power consumption is balanced by its exceptional performance in removing thick coatings and contaminants across large surface areas.

- 6000W Laser Cleaning Machine: The most powerful model, consuming 21-22 kW, is tailored for large-scale and heavy-duty cleaning tasks. While it requires more energy, it delivers the fastest and most efficient cleaning for the toughest industrial environments.

What Are The Disadvantages of Continuous Laser Cleaning Machines?

- Initial Cost: The upfront investment for a laser cleaning machine can be significant, especially for higher-powered models. While the long-term operational savings can offset the initial cost, it may still be a barrier for small businesses or companies with limited budgets.

- Power Consumption: Laser cleaning machines require substantial energy, particularly higher-powered models. This can lead to higher operational costs, especially for machines in the 3000W and 6000W range, which consume between 12-22 kW. For some operations, this could add to the cost of ownership.

- Surface Limitations: While laser cleaning is highly effective on metals and other robust materials, it may not be suitable for certain delicate surfaces, such as plastics or soft metals, which can be damaged by the intense heat generated by the laser.

- Need for Proper Training: Operating a continuous laser cleaning machine requires specialized knowledge and training. Improper handling could lead to suboptimal cleaning results or even damage to the surface being cleaned. Proper operator training and maintenance protocols are essential for maximizing the machine’s effectiveness.

- Fume and Dust Generation: The laser cleaning process generates fumes and particulate matter, which require adequate ventilation or a fume extraction system. Without proper air filtration, this can lead to an unsafe working environment or contamination in the surrounding area.

- Limited Mobility and Flexibility: While laser cleaning machines are efficient, they can be bulky and less flexible compared to portable cleaning options like abrasive blasting or chemical cleaning. The setup often requires a stable working surface and may not be ideal for certain field operations.

What Is The Service Life of Continuous Laser Cleaning Machines?

- Quality of Components: Higher-quality machines with durable parts such as the laser source, focusing optics, and cooling systems tend to last longer. Machines with premium components can often operate for 15 years or more without significant degradation.

- Usage Frequency: The more frequently the machine is used, the quicker certain components will wear out. For example, the laser source, depending on its type (e.g., fiber laser), may need to be replaced after a certain number of operating hours. Continuous or heavy-duty usage may reduce the lifespan slightly, while light use may extend it.

- Maintenance: Regular maintenance plays a crucial role in extending the service life. Tasks like cleaning the optics, inspecting the cooling system, and checking for any wear on moving parts can prevent premature breakdowns and ensure optimal performance. Machines that are properly maintained can often exceed their expected lifespan.

- Operating Conditions: Machines used in harsh environments (e.g., excessive heat, dust, or moisture) may experience more rapid wear and tear. Ensuring that the machine operates in controlled, optimal conditions can help preserve its longevity.

- Upgrades and Replacements: Some components, like the laser module or other electronic parts, may need to be upgraded or replaced over time. Keeping the machine updated with the latest parts can extend its usable life.

How To Maintain Continuous Laser Cleaning Machines?

- Regular Cleaning of the Optics: The laser optics (lenses and mirrors) can accumulate dust, dirt, or residue over time, which can reduce the effectiveness of the laser and cause damage to the components. Clean the optics regularly using lint-free wipes and recommended cleaning solutions. Always follow the manufacturer’s guidelines to avoid scratching or damaging the lenses.

- Check and Maintain the Cooling System: Continuous laser cleaning machines generate heat, so the cooling system plays a vital role in preventing overheating. Regularly check the cooling system for blockages, leaks, or low coolant levels. Ensure that fans, heat exchangers, and cooling pumps are working properly to maintain the correct operating temperature.

- Inspect the Laser Source: The laser source is one of the most critical components of the machine. Inspect the laser for any signs of wear, such as reduced power output or uneven beam focus. Depending on the type of laser used (e.g., fiber laser), follow the manufacturer’s recommendation for replacement cycles (e.g., after a set number of hours of operation).

- Clean and Lubricate Moving Parts: The moving components, such as the gantry, rails, and motors, should be kept clean and properly lubricated to prevent friction and ensure smooth movement. Apply lubricant to moving parts as per the manufacturer’s instructions to avoid wear and tear, and check for any misalignment or damage.

- Monitor Electrical Connections: Inspect all electrical connections, including wiring, switches, and circuit boards. Look for any signs of overheating, wear, or corrosion, and replace any damaged or worn parts. Ensure that connections are secure and not exposed to moisture or extreme conditions that could cause electrical malfunctions.

- Calibrate the Machine Regularly: Periodic calibration ensures that the laser beam is focused properly and that the machine is performing at peak efficiency. Calibrate the machine according to the manufacturer’s guidelines to ensure accuracy in cleaning and avoid any damage to the surface being cleaned.

- Check Fume Extraction Systems: Laser cleaning generates fumes and particulate matter. Ensure that the fume extraction system is working efficiently, with filters replaced as needed. This will not only improve air quality but also prevent the buildup of contaminants on the machine.

- Software and Firmware Updates: Continuous laser cleaning machines often come with software that controls various parameters. Keep the software and firmware updated to benefit from the latest features and improvements. Regular updates can also help resolve any bugs or issues that may affect performance.

- Perform Routine System Diagnostics: Many modern laser cleaning machines include diagnostic tools that can help identify potential problems early. Run system diagnostics regularly to catch any issues before they affect machine performance or lead to costly repairs.

- Follow Manufacturer Guidelines: Always refer to the manufacturer’s manual for specific maintenance instructions, recommended service intervals, and parts replacement schedules. Adhering to these guidelines will help maintain the warranty and ensure long-term functionality.

What Are The Customization Options Available For Continuous Laser Cleaning Machines?

- Double Wobble Cleaning Mode: This advanced mode allows for more efficient cleaning of larger surface areas by enabling the laser to move in a wobbling pattern. This creates a broader cleaning area and reduces the time required to clean large surfaces. It’s particularly useful for removing thick coatings or contaminants over wide regions.

- 3-in-1 Functionality: Some models offer 3-in-1 functionality, combining multiple cleaning features into a single system. This may include capabilities like surface preparation, rust removal, and paint stripping in one machine. This versatility allows users to adapt the machine for different cleaning needs without requiring additional equipment, providing significant cost savings and operational efficiency.

- Adjustable Cleaning Width: The ability to adjust the cleaning width is particularly valuable for working with varying surface sizes and cleaning requirements. By customizing the width, operators can optimize the machine’s performance for both small and large-scale jobs, ensuring faster cleaning times for larger areas while maintaining precision for smaller, more intricate surfaces.

Related Resources

Laser Marking VS Screen Printing

Laser Welding VS MIG Welding

Laser Rust Removal VS Sandblasting Rust Removal

Fiber Laser Cutting VS Plasma Cutting

Contact Us

Contact Information Form: