Introduction

Laser Cleaning Machines

-

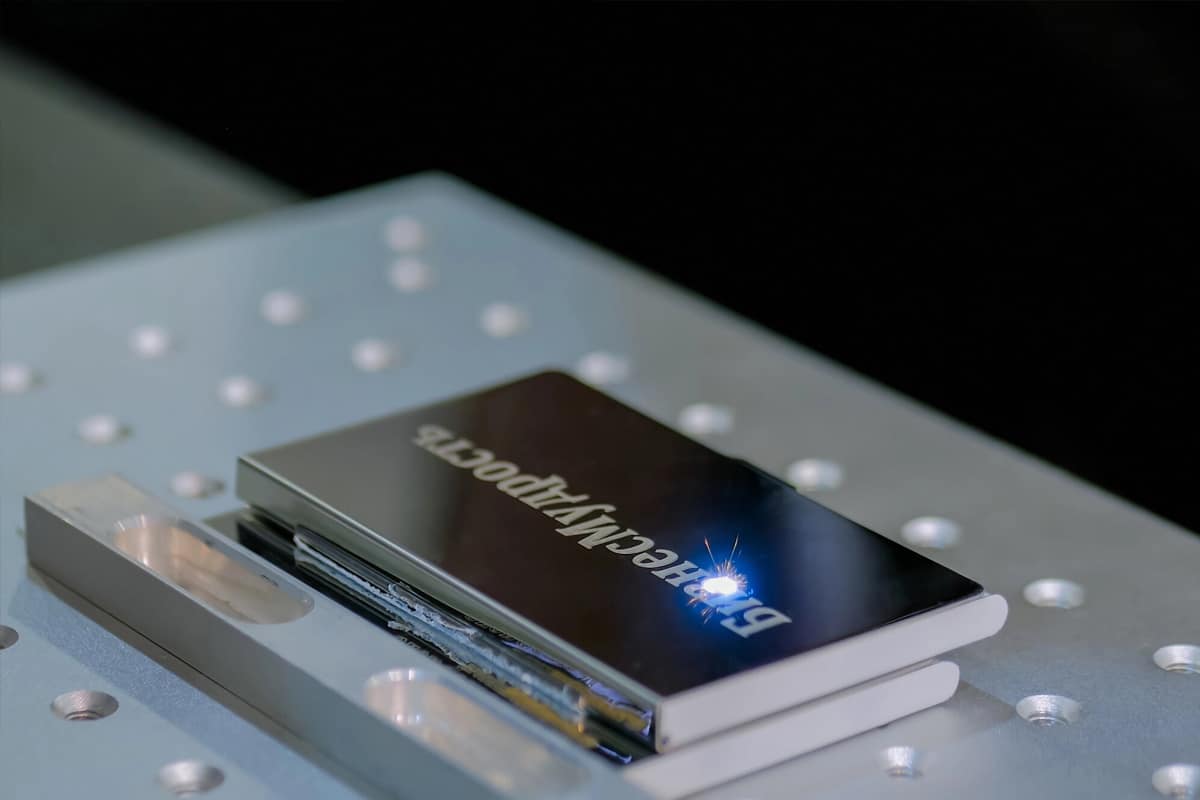

VIQ Laser Cleaning Machine

Rated 4.75 out of 5$3,800.00 – $8,400.00Price range: $3,800.00 through $8,400.00 Select options This product has multiple variants. The options may be chosen on the product page -

VIQ-P Laser Cleaning Machine

Rated 5.00 out of 5$3,700.00 – $8,300.00Price range: $3,700.00 through $8,300.00 Select options This product has multiple variants. The options may be chosen on the product page

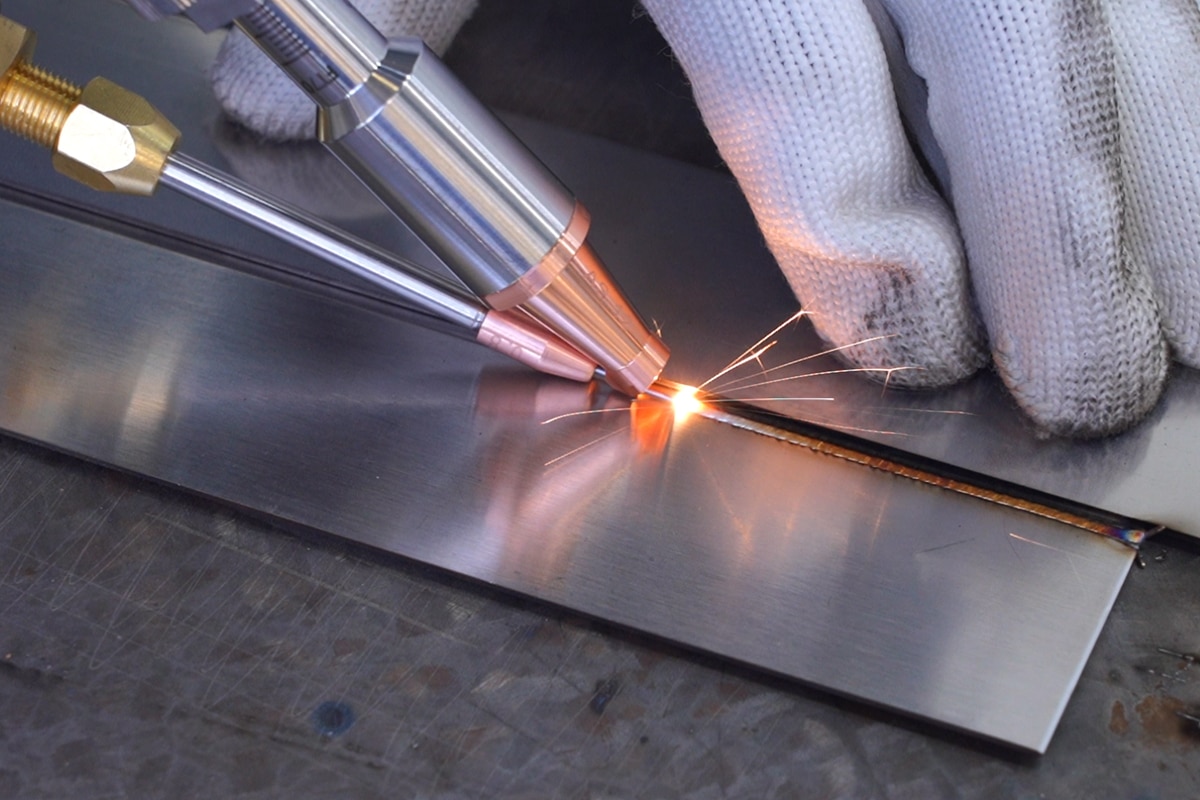

Applications

Advantages of Laser Cleaning

Eco-Friendly

Laser cleaning eliminates the need for toxic chemicals, solvents, or abrasive materials, significantly reducing environmental pollution. This environmentally responsible cleaning method produces minimal waste, promoting sustainability and supporting green manufacturing initiatives across various industries.

Precision and Accuracy

Laser cleaning offers exceptional precision, effectively removing rust, coatings, and contaminants without damaging the underlying surface. This ensures high-quality results, even on delicate or intricate components, making it ideal for industries where surface integrity is crucial.

Low Maintenance Requirements

With no moving parts or abrasive surfaces, laser cleaning machines have lower maintenance needs compared to traditional methods like sandblasting. This reduces the overall cost of ownership, increases operational uptime, and extends the lifespan of the equipment.

Cost-Effective Operation

Laser cleaning minimizes the use of consumables, such as chemicals and abrasives, reducing long-term operational costs. Its efficiency also cuts down on cleaning time, further saving labor and maintenance costs, making it a cost-effective solution for industrial cleaning.

Fast and Efficient Cleaning

Laser cleaning delivers rapid, effective results with minimal downtime. Its speed allows industries to maintain productivity and avoid prolonged interruptions in operations, making it ideal for high-demand environments where time efficiency is essential.

Versatile Application

Laser cleaning machines are adaptable to a wide variety of materials, from metals to plastics, and can handle diverse applications such as rust removal, surface preparation, and contamination cleaning, making them an excellent choice for industries with varied cleaning needs.

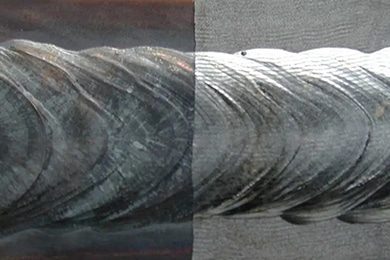

Comparison of Continuous and Pulse Laser Cleaning

| Feature | Continuous Laser Cleaning | Pulse Laser Cleaning |

| Operation | Delivers a constant, uninterrupted laser beam. | Delivers short, high-intensity laser pulses. |

| Cleaning Speed | Typically faster, suitable for large, continuous surfaces. | Slower but more precise, ideal for detailed or sensitive cleaning. |

| Heat Affected Zone (HAZ) | Larger heat-affected zone, increasing risk of material damage. | Smaller HAZ, reducing the risk of thermal damage to the material. |

| Surface Suitability | Best for cleaning large, flat, or thick surfaces. | Better for fine, delicate, or intricate surfaces that need precise cleaning. |

| Energy Efficiency | Less energy-efficient, as the laser runs continuously. | More energy-efficient, as energy is concentrated in short pulses. |

| Maintenance and Wear | Generally requires more maintenance due to constant use. | Lower wear and tear, as the laser is not constantly running. |

| Applications | Ideal for heavy-duty, high-speed industrial applications. | Best for applications requiring high precision and minimal impact. |

Customer Reviews

Frequently Asked Questions

What Is The Power of Laser Cleaning Machines?

- Continuous Laser Cleaning Machines

- 1000W: Suitable for light to medium-duty cleaning tasks such as surface rust removal, paint stripping, and debris cleaning.

- 1500W: Provides a balance between cleaning power and speed, making it ideal for medium-duty industrial cleaning applications.

- 2000W: Suitable for more intensive cleaning jobs, including the removal of thicker layers of contaminants and rust from larger surfaces.

- 3000W: Designed for heavy-duty cleaning in industrial environments, capable of handling more challenging cleaning applications, including high levels of rust or coatings.

- 6000W: High-power option for the most demanding industrial cleaning tasks, offering exceptional efficiency and fast cleaning for large-scale surfaces and heavy-duty industrial applications.

- Pulse Laser Cleaning Machines

- 100W: Ideal for delicate cleaning tasks where precision is crucial, such as cleaning small parts or sensitive materials.

- 200W: Suitable for light to medium cleaning tasks, including rust removal and cleaning coatings from metal surfaces.

- 300W: Provides a good balance between cleaning efficiency and precision, ideal for a wide range of industrial applications.

- 500W: A popular power range for many industrial applications, offering a faster cleaning rate for tougher contaminants and larger surfaces.

- 1000W: Effective for heavy-duty cleaning tasks, such as cleaning large areas, removing thick layers of rust or coatings, and preparing surfaces for further processing.

- 2000W: High-power laser cleaning machine used for the most demanding cleaning applications, including large-scale industrial projects and deep cleaning of heavily contaminated surfaces.

How Much Do Laser Cleaning Machines Cost?

- Continuous Laser Cleaning Machines: A 1000W continuous laser cleaning machine is priced at approximately $4,900, making it ideal for lighter industrial tasks such as removing rust or coatings from metal surfaces. A slightly more powerful 1500W machine is priced around $5,000, offering versatility for medium-duty applications. For more demanding industrial tasks, a 2000W continuous laser cleaning machine costs around $6,500, providing increased power for larger surfaces and faster cleaning. If you need to tackle heavy-duty cleaning jobs, the 3000W option, priced at $8,000, is designed for more intensive applications. For large, industrial-scale cleaning operations, the most powerful 6000W machine is available at $12,500, offering maximum power and cleaning speed for tough contaminants.

- Pulse Laser Cleaning Machines: Pulse laser cleaning machines also come in various power levels. The most basic 100W pulse laser cleaning machine starts at $6,000 and can go up to $7,500, ideal for delicate and precise cleaning tasks. For slightly more power, the 200W model ranges from $7,000 to $9,500, suitable for light to medium cleaning applications, such as rust removal or cleaning coatings. A 300W pulse laser cleaning machine, priced between $8,500 and $11,500, offers a good balance of power and precision for a variety of industrial tasks. The 500W machine, at $17,500 to $18,500, is ideal for faster cleaning and handling tougher contaminants. For large-scale operations, the 1000W pulse laser cleaning machine costs between $29,000 and $30,000, offering fast and effective cleaning for larger areas or thicker coatings. The most powerful 2000W pulse laser cleaning machine is priced between $66,000 and $70,000, designed for the most demanding cleaning tasks in heavy-duty industrial settings.

Why Are Laser Cleaning Machines So Expensive?

- Advanced Laser Technology: The core technology behind laser cleaning machines involves high-powered lasers that are precision-engineered for effective surface cleaning. The creation of these lasers requires sophisticated technology and materials, such as fiber optics, and advanced cooling systems. These components are costly to develop and manufacture, which drives up the price of the machines.

- Precision and Control: Laser cleaning machines are designed to provide highly controlled, precise cleaning without damaging the underlying material. This level of precision requires advanced software, high-resolution optics, and automated systems, all of which add to the cost. Additionally, features like adjustable power settings, beam focus control, and high-speed scanning systems contribute to their complexity and price.

- Durability and Industrial Build: Laser cleaning machines are built to withstand heavy industrial use, requiring robust materials and manufacturing standards. High-quality components that are durable enough for continuous operation in demanding environments (such as factories and construction sites) contribute to the overall cost. These machines are designed to be long-lasting, minimizing the need for frequent repairs or replacements, which makes the initial investment higher but more cost-effective over time.

- Specialized Cooling Systems: High-power laser cleaning machines generate significant heat during operation. To prevent overheating and ensure consistent performance, these machines are equipped with advanced cooling systems. These cooling systems, which often involve water or air cooling circuits, are complex and expensive to design and maintain, adding to the overall cost.

- Research and Development: Continuous investment in research and development (R&D) is necessary to advance laser cleaning technology, improve efficiency, and meet regulatory standards. The costs associated with R&D, including the testing of new technologies, regulatory compliance, and performance optimization, are factored into the price of the machines.

- Customization and Versatility: Laser cleaning machines are highly customizable to meet the specific needs of various industries, whether it’s for cleaning delicate surfaces, removing industrial coatings, or preparing metal surfaces for further processing. This versatility and ability to tailor the machine to the user’s needs require advanced design and engineering, which also increases the cost.

- Low Maintenance and High Efficiency: One of the key advantages of laser cleaning machines is their low maintenance requirement compared to traditional cleaning methods. The durability, precision, and efficiency offered by these machines reduce downtime and maintenance costs in the long run. However, this durability and efficiency are built into the machine’s high initial cost, which is compensated by long-term savings.

- Regulatory Compliance and Safety Standards: Laser cleaning machines must comply with rigorous safety and environmental standards. Manufacturers invest significant resources to ensure that their machines meet local and international regulations on laser safety, environmental impact, and energy efficiency. These compliance measures are reflected in the price of the equipment.

What Is The Power Consumption of Laser Cleaning Machines?

- For continuous laser cleaning machines, the power consumption increases as the power output of the machine increases. A 1000W continuous laser cleaning machine consumes between 4.5 to 5 kW of power. The 1500W model requires slightly more energy, consuming 6 to 7 kW, while a 2000W continuous system draws between 8 to 9 kW. For more intensive cleaning tasks, the 3000W machine consumes 12 to 13 kW, and the highest power model, the 6000W, demands a substantial 21 to 22 kW of energy to operate, making it ideal for large-scale, heavy-duty cleaning jobs.

- On the other hand, pulse laser cleaning machines generally consume less power than their continuous counterparts, though this also increases with the power rating. The 100W pulse laser model is the most energy-efficient, using 0.8 to 1.2 kW, while the 200W system consumes 1 to 1.5 kW. The 300W pulse model requires 2 to 2.5 kW of power, and a 500W pulse laser cleaning machine uses 3 to 4 kW. For larger industrial cleaning tasks, the 1000W machine consumes 4.5 to 5 kW, and the most powerful 2000W pulse laser machine requires 8 to 9 kW.

What Are The Disadvantages of Laser Cleaning Machines?

- High Initial Cost: Laser cleaning machines are a significant investment, with prices varying depending on power output and features. Higher-power models, such as those designed for industrial use, can be very expensive. This initial cost may be prohibitive for some businesses, especially smaller operations with limited budgets.

- Energy Consumption: Despite their high efficiency, laser cleaning machines can consume substantial amounts of energy, particularly at higher power levels. This may lead to increased operational costs, especially for large-scale or long-duration cleaning tasks. The need for advanced cooling systems can also add to overall energy consumption.

- Limited Effectiveness on Certain Materials: Laser cleaning technology works best on materials like metal, rust, and paint, but may not be as effective on more delicate surfaces or substrates such as ceramics, glass, or plastics. In some cases, improper settings could lead to damage or insufficient cleaning.

- Skill and Training Requirements: Operating laser cleaning machines requires a certain level of technical expertise. Operators need to be trained to handle the machines properly, including adjusting settings, maintaining the system, and ensuring safety protocols are followed. Inexperienced users might struggle to achieve optimal cleaning results or even risk damaging the equipment or workpieces.

- Maintenance Costs: While laser cleaning machines are generally low-maintenance compared to traditional cleaning methods, they still require regular servicing, especially when dealing with high-powered systems. Components such as lasers, optics, and cooling systems need to be maintained or replaced periodically, leading to ongoing maintenance costs.

- Health and Safety Risks: The high-powered lasers used in cleaning machines can pose safety risks, including potential eye damage or skin burns. As a result, proper safety protocols, including protective gear like goggles, gloves, and shields, must be strictly followed to ensure operator safety. Additionally, the potential for high-intensity light exposure means that work areas must be appropriately controlled.

- Limited Range for Complex Contaminants: Laser cleaning machines are effective at removing surface contaminants like rust, paint, and coatings, but may struggle with more complex or deeply ingrained contaminants, especially those that have chemically bonded with the surface. In such cases, additional cleaning methods may be required for thorough removal.

How To Choose Laser Cleaning Machines?

- Determine the Type of Cleaning Task

-

The first step is to assess the cleaning task at hand. Laser cleaning is suitable for removing rust, paint, coatings, and other contaminants from metal surfaces. If you need to clean delicate or non-metal materials, like plastics or ceramics, ensure the machine you choose is compatible with those substrates. Some lasers are more effective on specific materials, so understanding your application is key to selecting the right technology.

- Select the Right Power Output

-

Laser cleaning machines come in various power ratings, typically ranging from 100W to 6000W. The power you need depends on the scale of your cleaning task:

- Low-power models (100W – 500W) are ideal for small-scale or precision cleaning, such as removing light contaminants, cleaning intricate parts, or handling delicate components.

- Medium-power models (500W – 1000W) are best for more substantial cleaning tasks, such as removing heavier rust or paint in industrial settings.

- High-power models (1000W and above) are suited for large-scale cleaning applications, such as heavy-duty industrial rust removal or cleaning large surfaces.

- Consider the Cleaning Speed

-

Faster cleaning can increase productivity, so consider the speed requirements of your operation. High-powered laser cleaning machines tend to clean faster due to their increased energy output. However, the cleaning speed also depends on the size of the surface area being treated and the thickness of the contaminants. If you have a large area or need to clean quickly, opt for a more powerful system with higher processing speeds.

- Understand the Maintenance Requirements

-

While laser cleaning systems require less maintenance than traditional methods, regular upkeep is still necessary to keep the machine running smoothly. Check the maintenance requirements of the machine, such as the frequency of cleaning the laser system, replacing parts like lenses and filters, and ensuring proper cooling. Choose a machine that offers easy maintenance and support from the manufacturer.

- Consider Your Budget

-

Laser cleaning machines can be expensive, with prices ranging significantly based on power output and additional features. While high-power models may offer faster and more efficient cleaning, they come with a higher price tag. Consider your budget and balance it with the machine’s performance requirements. Additionally, factor in ongoing operational costs such as electricity, maintenance, and potential downtime.

- Evaluate Safety Features

-

Laser cleaning machines generate high-intensity laser beams that can be hazardous if not handled properly. Ensure the machine you choose includes necessary safety features, such as:

- Laser safety enclosures to prevent exposure to harmful radiation

- Safety interlocks that shut the machine down if the enclosure is opened

- Proper shielding and protective goggles for operators

- Remote controls or automated features to minimize operator exposure.

- Look for Versatility and Customization

-

Some laser cleaning machines offer customizable settings and attachments, allowing you to adjust the beam intensity, focus, and cleaning speed to suit different materials and tasks. If your work involves cleaning various types of surfaces or contaminants, choose a machine that offers versatile features to handle a broad range of applications.

- Check Manufacturer Support and Warranty

-

Choose a reputable manufacturer that offers robust customer support, including installation assistance, operator training, and troubleshooting services. Additionally, ensure the machine comes with a comprehensive warranty to cover any potential defects or issues during the early years of operation. Long-term support can save you time and money in the future.

What Is The Service Life of Laser Cleaning Machines?

- Typical Lifespan: A well-maintained laser cleaning machine typically has a service life of 10 to 15 years. This can vary depending on the model and manufacturer, as some high-quality machines may last even longer. The laser source itself, usually a fiber laser, is one of the most important components and can last up to 100,000 hours of operation under optimal conditions.

- Laser Source Lifetime: The laser source is a critical part of the machine, and its lifespan is often cited in hours of use. Fiber lasers typically have a lifetime of 50,000 to 100,000 hours. After this period, the laser source might begin to degrade, resulting in reduced efficiency or output power. Regular servicing and proper handling can extend the life of the laser source.

- Other Components’ Lifespan: Other parts of the laser cleaning machine, such as the optics, cooling system, and power supplies, also contribute to the overall lifespan. These components can wear out over time due to constant use, dust, and environmental factors. With regular maintenance, these parts can last for several years, though periodic replacements may be necessary to keep the machine operating at peak efficiency.

- Maintenance Impact: Proper maintenance plays a crucial role in extending the life of the laser cleaning machine. Regular cleaning of the laser head, lenses, and cooling systems, as well as monitoring the machine’s performance, can help prevent premature wear and tear. Additionally, following the manufacturer’s guidelines for operation and care can help avoid overuse or misuse that could shorten the machine’s lifespan.

- Operating Conditions: The environment in which the laser cleaning machine operates also impacts its longevity. Machines used in harsh or dirty environments, such as heavy industrial settings, may experience more wear and require more frequent servicing. Keeping the machine in a clean, cool, and dry area with proper ventilation can extend its operational life.

What Is The Difference Between Pulse And Continuous Laser Cleaning Machines?

- Mode of Laser Emission

- Pulse Laser Cleaning Machines: These machines emit laser light in short, high-energy pulses. The laser beam is delivered in rapid bursts, typically measured in nanoseconds or picoseconds. Each pulse delivers a significant amount of energy over a very short duration, which causes the contaminants to vaporize or be blown away by the thermal shock. Pulse lasers are ideal for cleaning small or detailed areas, as well as materials sensitive to heat.

- Continuous Wave (CW) Laser Cleaning Machines: In contrast, continuous wave lasers emit a steady beam of laser light without interruptions. The laser energy is applied continuously, which can lead to more uniform and consistent cleaning. CW lasers are typically more suitable for larger surfaces and industrial cleaning tasks that require sustained energy application.

- Laser Power and Energy

- Pulse Laser Cleaning Machines: Pulse lasers usually operate at lower average power but deliver much higher peak power in each pulse. This high peak power makes them effective at removing tough contaminants without damaging the underlying material. The energy density of each pulse is sufficient to vaporize or ablate contaminants effectively.

- Continuous Wave (CW) Laser Cleaning Machines: CW lasers generally operate at a higher average power over an extended period, making them suitable for larger surface areas or tasks that require sustained cleaning. However, they might not provide the same intensity or impact as pulse lasers for very stubborn contaminants.

- Efficiency and Cleaning Speed

- Pulse Laser Cleaning Machines: Pulse lasers tend to be more efficient for delicate or precision cleaning jobs, as the high-energy pulses are very effective at dislodging contaminants. However, due to the intermittent nature of the pulses, the overall cleaning speed can be slower when dealing with large surfaces or non-precision tasks.

- Continuous Wave (CW) Laser Cleaning Machines: CW lasers are typically faster for cleaning larger areas because they provide a constant energy output. This makes them ideal for industrial cleaning tasks, such as rust or paint removal over broad surfaces. CW lasers tend to be more efficient in cleaning applications where the removal of coatings or contaminants is less detailed and more uniform.

- Material Suitability

- Pulse Laser Cleaning Machines: These are more versatile when it comes to cleaning a variety of materials, including those that are heat-sensitive or delicate. The pulsed nature of the beam prevents prolonged heat exposure, minimizing the risk of damaging the substrate material.

- Continuous Wave (CW) Laser Cleaning Machines: While CW lasers are excellent for industrial applications involving metal surfaces, such as steel or aluminum, they might not be as suitable for materials sensitive to heat or those that could be damaged by prolonged exposure to the laser.

- Cooling and Maintenance

- Pulse Laser Cleaning Machines: Since pulse lasers deliver high-energy bursts over a very short time, they generate less heat overall compared to CW lasers. This can reduce the demands on the cooling system and make maintenance easier in some cases. However, the components handling the high pulse energy must be well-maintained.

- Continuous Wave (CW) Laser Cleaning Machines: CW lasers require more cooling since they generate continuous heat. As a result, these systems may need more robust cooling mechanisms (e.g., water or air cooling systems) to maintain the operational temperature and prevent overheating.

- Cost and Application Range

- Pulse Laser Cleaning Machines: Generally, pulse laser systems tend to be more expensive due to the complexity of the technology required to generate short, high-energy pulses. However, they are more versatile, especially for precision cleaning in smaller or more detailed tasks.

- Continuous Wave (CW) Laser Cleaning Machines: CW systems are typically less expensive compared to pulse lasers, especially for high-powered applications. They are cost-effective for large-scale industrial cleaning where speed and efficiency are crucial. However, they may not be as suitable for applications requiring delicate cleaning or minimal heat impact.

Related Resources

2026 Best CO2 Laser Cutter for Small Business

Laser Marking VS Screen Printing

Laser Welding VS MIG Welding

Laser Rust Removal VS Sandblasting Rust Removal

Contact Us

Contact Information Form: