As global manufacturing keeps moving toward automation, adaptability, and precise production, selecting sheet metal processing technology turns into a key business choice, not just a technical one. Data from the laser equipment field reveals that worldwide need for laser-based manufacturing systems has risen steadily. Europe, North America, and South Asia make up more than 57% of total equipment buying in 2025. Meanwhile, platform stats show the laser equipment sector saw about 26% more traffic year-over-year. Purchase inquiries jumped by over 40%. This highlights a clear shift from old-school mechanical processing to digitally managed, accurate solutions.

In this setting, laser cutting machines stay as the top searched and reviewed option in metal fabrication. This shows manufacturers’ rising focus on design versatility, surface finish, and ongoing growth potential. Now, comparing CNC punching machines and laser cutting systems goes beyond which is more modern. Instead, it asks which method fits best with output levels, material variety, expense setup, and plans for future growth. So, grasping the basic contrasts between these two approaches matters a lot for current fabrication companies aiming for lasting edge in the market.

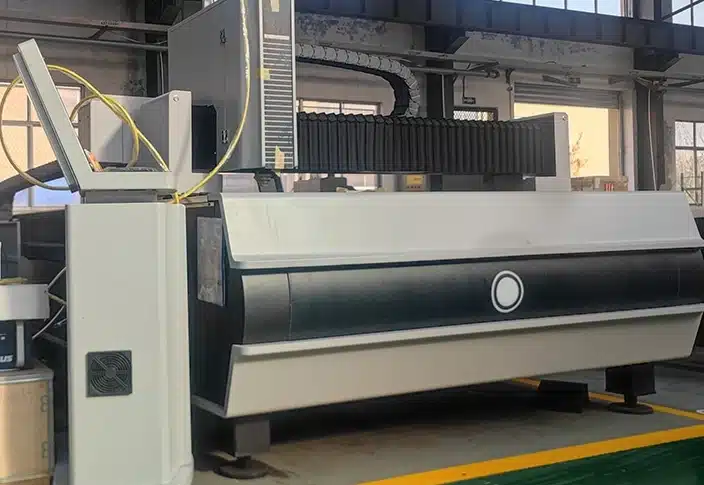

For top-quality equipment, Victory Industry emerges as a worldwide frontrunner in sophisticated laser setups. Their range of fiber laser cutting machines combines strong output, adaptability, and tough build for industry use. These suit everything from modest workshops to big production lines.

Cutting Mechanism and Material Interaction

How Do CNC Punching and Laser Cutting Mechanisms Differ?

CNC punching machines operate by exerting physical pressure via a tool and die to form holes or patterns in sheet metal. It involves a direct shaping process. This approach works well for repeated jobs with set shapes. On the other hand, laser cutting relies on a powerful light ray to soften, scorch, or evaporate the material with great precision.

Fiber laser cutting machines draw from a solid laser origin sent via optical fiber. Such tech allows touch-free, heat-driven handling that cuts down on physical strain to the material.

The VIE Laser Cutting Machine and VIB Laser Cutting Machine from Victory Industry are built to maintain steady cut results on stainless steel, carbon steel, and aluminum. Their superior laser cutting head guarantees neat and precise edges with little thermal warping. This holds even for tricky shapes.

Material Suitability and Thickness Range

Which Materials and Thicknesses Are Each Method Best For?

CNC punching performs strongly when dealing with slim sheets that need standard hole designs or raised details. Still, it grows less effective or even unfeasible for heavier sheets or uneven forms.

Laser cutting covers a wider array of materials and handles greater thicknesses. High-strength fiber lasers commonly process moderate to heavy metal sheets while keeping good edge finishes. The VIB machine manages power up to 20,000W. This fits tough tasks in car making or building steel sectors.

Moreover, the VIB laser cutting machine suits exact, demanding metal work in many fields.

CNC Punching Machine vs Laser Cutting Machine: Key Comparison Table

| Comparison Aspect | CNC Punching Machine | Fiber Laser Cutting Machine |

| Cutting principle | Mechanical force using punch and die | Thermal cutting using focused laser beam |

| Material contact | Direct contact with sheet metal | Non-contact processing |

| Suitable materials | Mainly thin carbon steel, stainless steel | Carbon steel, stainless steel, aluminum, brass, copper |

| Typical thickness range | Thin sheets, usually under 3–4 mm | Thin to thick plates, depending on power (up to 20 mm+ for steel) |

| Shape flexibility | Limited by punch tooling shapes | Excellent for complex and free-form geometries |

| Edge quality | May require secondary deburring | Smooth edges, minimal post-processing |

| Tooling requirement | Frequent tool changes and wear | No physical tools, only optical consumables |

| Setup and changeover | Longer setup time for new designs | Fast changeover via software programs |

| Automation compatibility | Moderate | Highly compatible with Industry 4.0 automation |

| Operating noise & vibration | Higher due to mechanical impact | Lower, smoother operation |

| Long-term scalability | Limited by tooling and mechanical structure | Easily scalable with software and automation upgrades |

Edge Quality and Post-Processing Requirements

How Does Each Method Affect Edge Finishing?

Laser cutting creates even smoother borders with hardly any rough edges. Often, this removes the necessity for extra smoothing or polishing steps. As a result, it speeds up the flow to later stages.

By comparison, CNC punching might produce tool scratches or rough spots based on tool condition and material flexibility. Therefore, you could need to spend on more finishing equipment or workforce.

The VIB Laser Cutting Machine delivers tidy, exact cuts with slight heat warping. This applies even to denser materials. Its precise linear rails and servo motors aid smooth movement and reliable edge results.

Production Efficiency and Speed Considerations

Which Method Is Faster for Batch Production?

When handling large runs with similar designs, CNC punching gains an edge thanks to its tool holder setup. This lets it quickly shift among different punches. However, it falls short in handling diverse part forms.

Laser cutting fits better for mixed product ranges or tailored pieces. The VIE laser cutting machine offers outstanding cut standards, pace, and output. Its robust servo motors enable rapid starts and stops. Yet it keeps cut exactness intact.

What About Setup Time and Tool Changes?

CNC punching demands hands-on tool swaps. These can extend preparation time a lot. This issue arises especially when moving between different parts or materials.

Laser cutting avoids this issue completely. Through smart software controls, you can switch from one layout to the next without hardware tweaks. Plus, simple links to automated tools and intelligent factory networks enable smooth batch management.

Victory Industry supplies automated systems. Examples include loading and unloading robots along with storage towers. These help shorten cycle durations further.

Can These Machines Be Integrated Into Smart Factories?

Laser setups connect much more readily into Industry 4.0 settings. Victory Industry delivers ready-to-link options with their laser machines. These back Industry 4.0 setups.

Cost Implications of CNC Punching vs Laser Cutting

What Are the Upfront Equipment Costs?

CNC punching machines typically demand a smaller starting outlay. However, once you include tool expenses and limits in shape options, that benefit begins to fade.

Laser cutters such as the VIE call for a bigger initial spend. But they yield better returns over time via flexibility and lower manpower needs.

Victory Industry provides affordable rates for its full laser cutting selection. This includes adaptable payment plans tied to your output size.

How Do Operating Costs Compare?

Tool degradation in CNC punching brings ongoing costs. Laser cutters use more power. This is true particularly at peak power settings. Yet they require fewer replaceable parts.

Victory Industry’s power-saving laser systems aid in cutting down extended running expenses. Options like smart gas regulation and self-adjusting heads improve usage efficiency. At the same time, they preserve strong performance.

What About Maintenance and Longevity?

Punch presses feature numerous parts in constant motion and pressure. You must service dies, supports, and fluid systems often.

Fiber lasers prove more dependable. Their low upkeep stems from lacking mirrors and having protected light paths. This boosts runtime steadiness.

Both VIE and VIB models come with modern control setups. These allow ongoing oversight. Thus, they simplify forward-looking upkeep.

Design Flexibility and Application Scope Comparison

Which Technology Handles Complex Shapes Better?

Laser setups claim a clear win in this area. The advanced laser cutting head provides neat and exact cuts with little heat warping. This works well even for intricate forms.

CNC punching faces limits from the actual forms of its tools. You can make special punches. But these raise expenses and delay times.

Can They Handle Marking or Perforation Tasks?

Punching can form standard hole patterns swiftly. However, it offers little in terms of fine details or refinement.

Fiber lasers manage inscribing, labeling, tiny holes. They do all this in a single run. In fact, lasers permit marking, etching, inscribing, and small perforations during one operation.

Consequently, they work perfectly for sectors needing tracking or ornamental touches.

Which Industries Are They Best Suited For?

Punching succeeds in areas like air conditioning panels, power boxes, and bulk-made supports. Here, quickness outweighs looks.

Laser cutting leads in fields such as aircraft building, vehicle production, health tools, and tech gadgets. In these, precision and surface quality remain essential.

Victory Industry aids various sectors via adjustable machine setups.

Material Waste Management and Sustainability Factors

Which Method Minimizes Scrap Better?

Laser cutters feature narrower cut lines than punched openings. Therefore, you can arrange parts closer together on a sheet. Over time, this saves resources.Software bundled with Victory Industry’s machines refines part arrangements to lessen waste.

What Are the Energy Usage Differences?

CNC punching draws less electric power per task. But it handles varied parts less well in a single session.Fiber lasers draw less power than past CO₂ lasers. Still, they use more than mechanical punches.Victory’s high-output power units help narrow this difference. Meanwhile, they sustain top performance.

How Is Scrap Handled?

Punching yields removable pieces that recycle easily. Lasers produce small particles or melted leftovers. These require air cleaning.Victory Industry builds waste handling features into their machine bases. This smooths out removal steps.

Precision Tolerances and Repeatability Metrics

How Accurate Are These Methods?

Laser cutting reaches finer allowances. These often stay within ±0.05 mm over an entire sheet. The VIE Laser Cutting Machine provides placement accuracy of 0.05 mm.Punching precision drops gradually from tool use and part strain.

Is Repeatability Consistent Over Time?

Fiber lasers form closed systems with motor-controlled motion. They show little shift even after many runs.With Victory’s solid construction, both models guarantee steady results during nonstop use.

Do They Meet Industry Tolerance Standards?

Laser machines usually follow ISO 9013 Class 2 guidelines or finer. CNC punch presses might require follow-up work to reach matching levels.Machines from Victory Industry are crafted to match worldwide production rules in several areas.

Choosing the Right Machine Based on Project Needs

Should You Prioritize Volume or Design Variety?

If you make thousands of matching parts each day, punching could fit.

Nevertheless, if your work includes regular design shifts or limited batch sizes, laser cutting adapts much better.

Victory’s consultation team can assist in assessing which model. Options include the VIE or VIB. They align with your output needs.

How Critical Is Surface Finish and Material Type?

Flexible metals or covered surfaces gain from no-touch handling through lasers. If surface standard counts highly, even during fast runs, laser stands as the prime pick.

Both Victory models process stainless steel, aluminum mixes, brass, and carbon steel. They do so with little border changes.

Can the System Scale as Your Needs Grow?

Laser setups provide add-on improvements. These cover fresh software tools, robot modules, and online data review. Such features lengthen service life without total swaps.

Punching arrangements often need tool renewals or fresh holders as lines change.For sustained expansion, laser tech holds the advantage. This is especially so with Victory’s customization services.

FAQ

Q1: Can a laser cutting machine replace a CNC punching machine entirely?

A: Not always. If your production involves repetitive forms like louvers or countersinks that require deformation instead of cutting, punching remains necessary.

Q2: How long does it take to train staff on laser cutting?

A: Victory Industry provides training as part of installation support. Most operators become proficient within a few days due to intuitive interfaces.

Q3: Is it worth investing in automation add-ons immediately?

A: If you’re running multi-shift operations or aiming for unmanned production overnight, yes. Otherwise, modular upgrades can be done later as needed.

Q4: What’s the average lifespan of a fiber laser system?

A: With proper maintenance and usage within rated parameters, Victory’s fiber lasers often exceed 100,000 hours of operation without major failure.

Q5: Can I use one laser system for both thin sheets and thick plates?

A: Yes. Victory’s models support power levels from 1500W up to 20kW+, allowing versatility across material thicknesses without changing hardware.