Technological Innovation

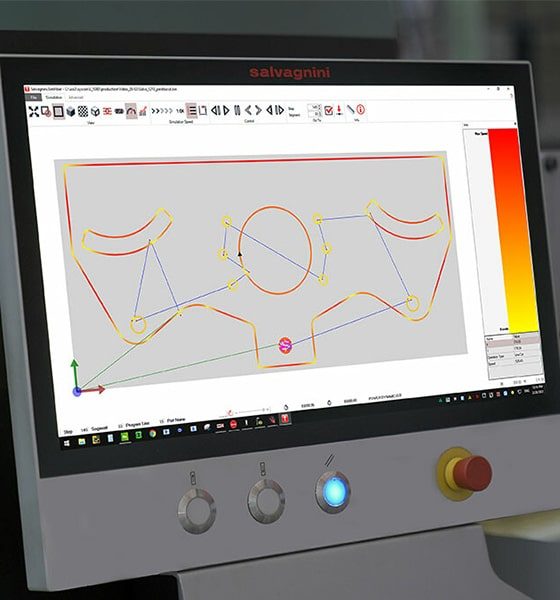

Advanced Laser Technology

Customization And Adaptability

Artificial Intelligence And Automation Integration

Integration of IoT And Connectivity

Research And Development

Victory Industry’s commitment to technological advancement is underpinned by strong research and development (R&D) initiatives. Our research and development work is the cornerstone of innovation, promoting continuous improvement and the exploration of emerging technologies.

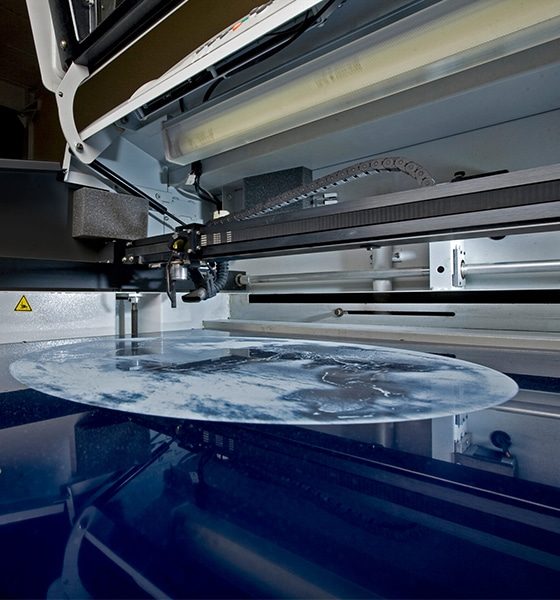

State-of-The-Art R&D Facilities

Our state-of-the-art research and development facilities underscore Victory Industry's commitment to remain at the forefront of technological innovation. These facilities feature cutting-edge laboratories, test environments, and collaborative spaces where our interdisciplinary teams of engineers, physicists, and technical experts work together to push the boundaries of laser technology.

Continuous Improvement Culture

Our commitment to excellence is reflected in our continuous improvement framework within our research and development processes. Regular feedback loops, post-implementation reviews, and lessons-learned sessions help improve our products and processes. This iterative approach ensures that each generation of laser equipment surpasses the previous generation in performance, reliability, and sustainability.

Pay Attention to Emerging Technologies

Victory Industry allocates significant resources to research emerging technologies related to laser applications. From nanosecond to femtosecond laser systems, additive manufacturing technologies, and advances in laser optics, our R&D efforts are dedicated to staying at the forefront of technological breakthroughs. By anticipating future trends, we position ourselves to lead, rather than follow, the fast-paced world of technological innovation.

Human Capital Investment

Victory Industry recognizes the importance of cultivating talents to drive technological innovation. We invest in training programs, workshops, and knowledge-sharing programs to enhance the capabilities of our R&D teams. This investment in human capital ensures our team can keep up with the latest advancements, fostering a culture of innovation and expertise within the organization.

Customized Maintenance Plans

Energy Saving Solutions

Sustainable Design Principles

Environmentally Laser Technology

Waste Reduction Strategies